Optical Edition

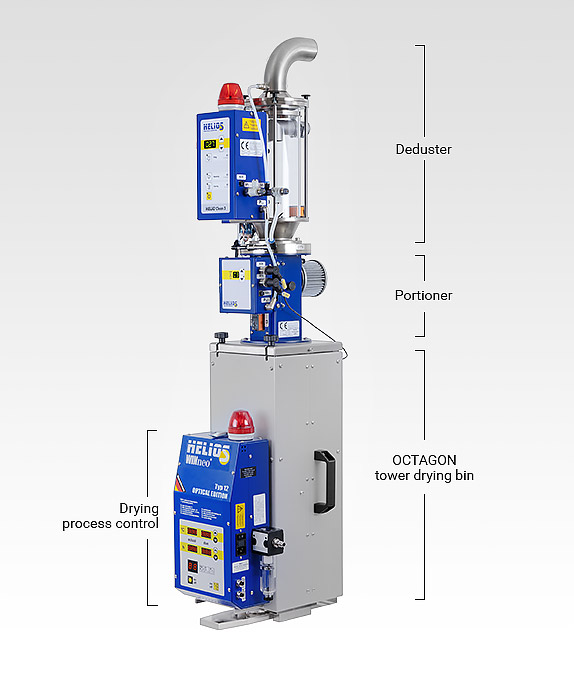

HELIO®Clean - Deduster Dryer

Filling + Dedusting + Drying

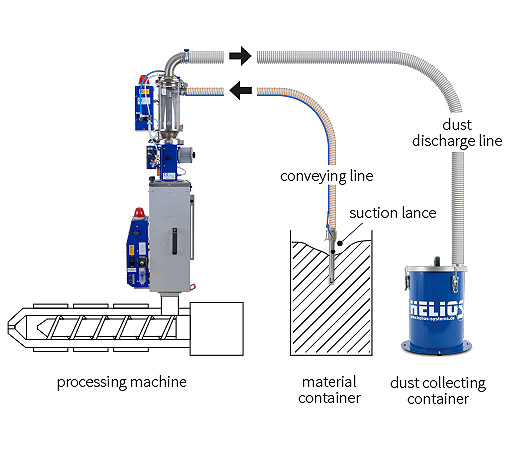

Compact material preparation unit for the highest demands in injection moulding of optical parts. The unit consists of a dedusting device with integrated feeding technology and portion-wise transfer of the dedusted granulate into a tower drying bin with a scalable filling height, which is flown through with a drying gas from a drying process control.

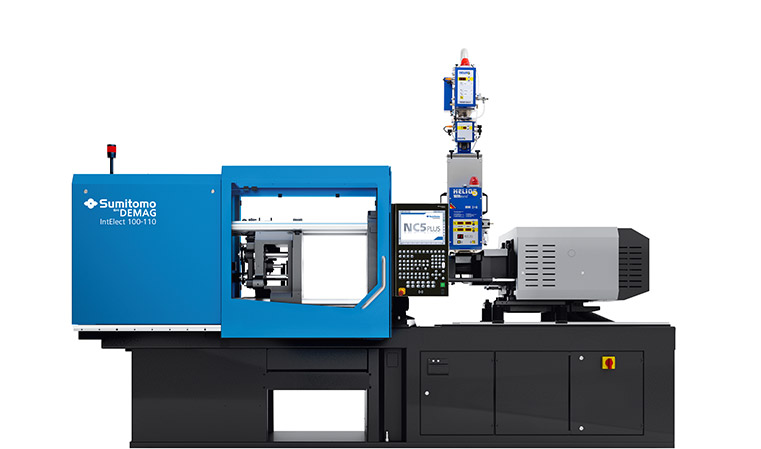

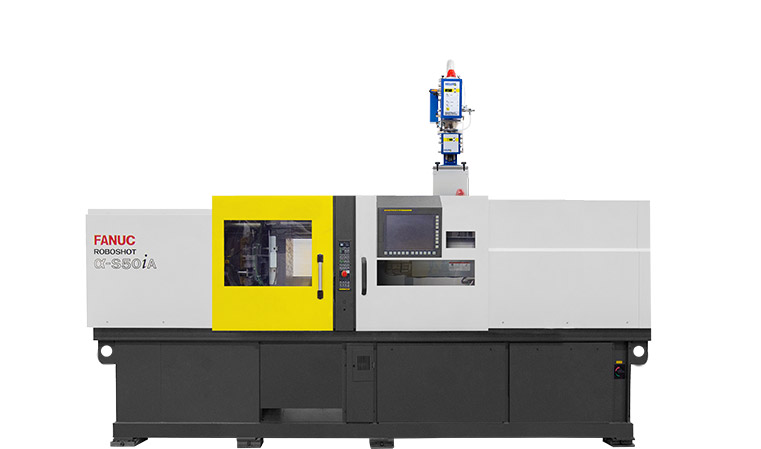

- mounting directly on an injection moulding machine

- special glass / stainless steel

- blow cone, Al nickel plated

- self-cleaning blowing nozzles

- locking cone hardened stainless steel

- dedusting by air sifting with ion shower

- optical display of sifter glass cleaning

- drying by dry air / nitrogen

DD-12 : material throughput 0,4 - 3 kg/h*

DD-24 : material throughput 0,8 - 6 kg/h*

* depending on the bulk material and the allowed drying time. The example is related to COC/COP/PC/PMMA

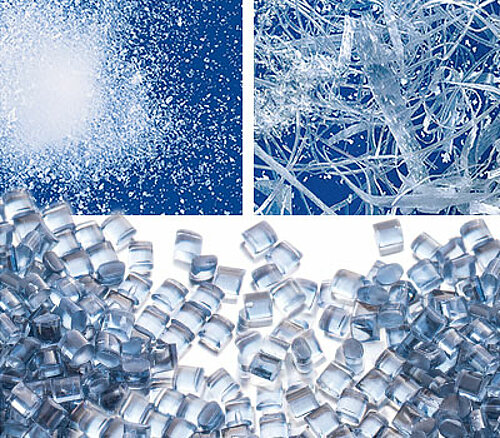

Air sifting with ion shower

The dust is removed by air sifting with highly effective ion shower. During whirling/circulation in the deduster, a continuous stream of ionised air is sucked through the portion to be dedusted. In the process, the binding forces between dust particles and granules are reduced to such an extent that the dust is loosened and can be separated by air sifting. Due to the special glass construction, the ions are particularly durable and thus enable a high efficiency of the ion shower.

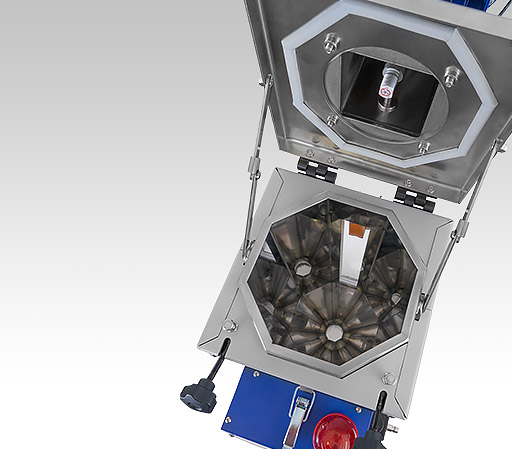

Sifter glass cleaning

The sifter glass is neutralized and cleaned with ionised air. The cleaning phase is made visually visible on the glass.

Tower drying bin

Tower drying bin in octagon construction

- octagonal inner container of stainless steel, fully insulated

- stiffening frame between inner tank and cladding

- powder-coated cladding sheet, very scratch-resistent

- optimal drying gas distribution

- viewing window

Viewing window

At the tower drying bin, the filling level can be continuously preselected between 2-10 liters or 4-20 liters by means of a sharable filling level sensor, depending on the throughput and the permissible dwell time.

Container lid can be folded down for cleaning

The container lid can be opened in just a few steps.The lid, together with the deduster is tilted 90° to the side. Two stable flap holders ensure a safe cleaning position.

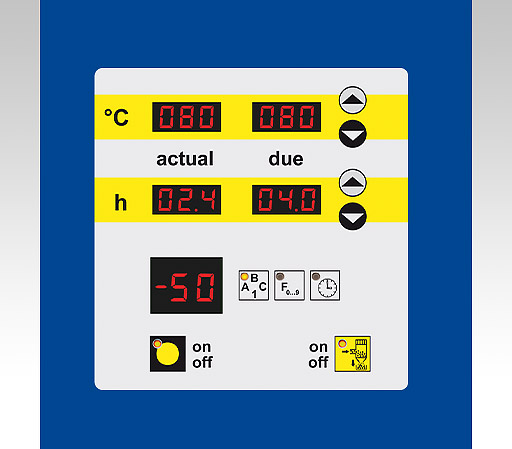

Process control

Control detachable

The drying process control can be easily detached from the tower drying bin by means of a clamping lock, i.e. in order to attach a bridging control during recalibration without interrupting production. Compressed air or nitrogen can be used as drying gas.

Drying Process Control

- heating capacity 1,0 kw

- drying gas flow rate

50 | 75 | 100 l/min or

60 | 90 | 125 l/min - compressed gas-based drying gas dryer with patented HELIOS digital pneumatics

- drying temperature range 30-150°C

- quick selection button for 3 drying intensities A, B, C

- portion drying programm 1

- selection button for 10 functions

- weekly timer

- display of drying temperature and drying time SET/ACTUAL as well as A,B,C, 1

- factory calibration with a calibration certificate for

- 2 drying temperatures

- 3 drying gas volume flows

- 2 dew points - overdrying protection depending on throughput

- conveying time control and

- material lack detection (Software)

- alarm lamp with potential-free contact

- dew point display down -50 °C

Deduster control

- dedusting portion

- air sifting

- sifter cleaning

- status display

- error messages

- time until ionizer maintenance

- reset to factory settings

- display of operating hours

- monitored forwarding of dedusted portion

DD-12 / DD-24 Optical Edition

| DD-12 | DD-24 | |

| material | special glas, stainless steel | |

| weight | 31,4 kg | 36,4 kg |

| material throughput * | 0,4 - 3 kg/h* | 0,8 - 6 kg/h* |

| dedusting portion | 0,38 liters to 0,5 liters | |

| conveying line | DN 32 | |

| conveying height | max. 8 m | |

| electrical connection | ~ 100 - 240 V AC, 50/60 Hz | |

| power consumption | max. 1,0 kW | |

| pneumatic connection | min. 6 bar, 2x 3/8“ | |

| compressed air quality | max. oil content ≤ 0,01 mg/m³ | |

| temperature range | 0 - 40 °C | |

* depending on the bulk material and the allowed drying time. The example is related to COC/COP/PC/PMMA

Machine adapter

- stainless steel gate valve

- dust-tight construction

- clamping lever for slide rail

L-guide rails made of steel (nickel-plated) optionally available for sliding rails [mm]: 80x15, 80x20, special measurements on request

Options:

- suction lance long 810 mm (instead of 380 mm)

- conveying hose set 5m (instead of 3m)

- dust collection container 16,5 liters (instead of 5,5 liters)

Do you have any questions about us or our products?

Just send us a quick message and we’ll gladly get back to you via phone or mail to answer any open questions.

Customer support service by telephone

We will gladly answer all open questions.

or use your own e-mail program:

Privacy policyThe data sent will only be processed for the purpose of processing your request. You can find further information in our data protection declaration. |