Zero-defect production thanks to HELIOS dedusting dryers

JETBOXX®

For the production of optical and medical parts

Filling + Dedusting + Drying

Compact material preparation unit for highest demands in injection moulding of optical parts. The unit consists of a dedusting device with integrated feeding technology and transfer of the dedusted granulate in portions into a tower drying container with a scalable filling height, which is flown through with a drying gas from a drying process control.

- Installation directly on injection moulding machine

- Special glass / stainless steel

- Surface finished dust removal cone

- Self-cleaning blowing nozzles

- Dedusting by air sifting with ion-shower

- Cleaning sifter glass with optical monitoring

- Stainless steel portioner

- Drying with dry air / nitrogen

Documented process via OPC UA interface

- Future-proof solution

- Simple installation via Ethernet

- Platform-independent

- Can be integrated with cloud, ERP systems or dashboards

- JETBOXX® dryers are in compliance with OPC UA

HELIOS deduster dryers for maximum cleaning and perfect drying result

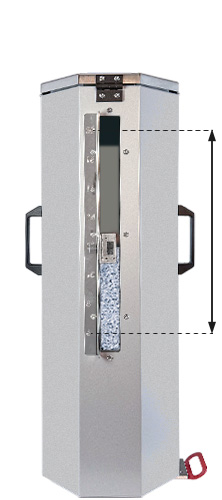

DD 12 "Optical Edition"

Tower Drying Container:

Octagon design for the best possible drying efficiency

Superclean included

DD 24 "Optical Edition"

Tower Drying Container:

Octagon design for the best possible drying efficiency

Superclean included

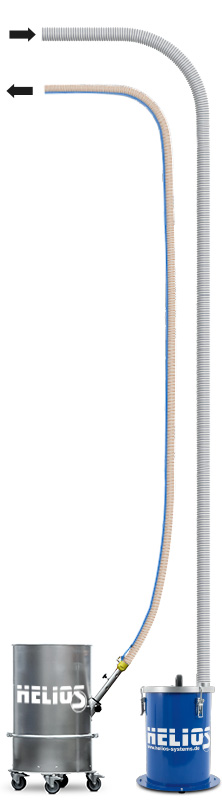

Conveying:

Day tank / Venturi-suction lance / conveying hose

Dust separation:

Dust collecting bin /

dust hose

DD 20 "Optical Edition"

Filling volume:

20 liters

Superclean included

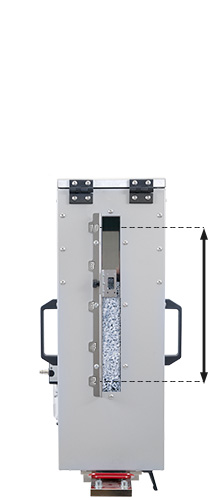

DD 30 "Optical Edition"

Variable filling volume:

20−30 liters

Superclean included

Technical Data

|

DD12 Optical Edition |

DD24 Optical Edition |

DD20 Optical Edition |

DD30 Optical Edition |

|

|---|---|---|---|---|---|

| Throughput* [kg/h] |

0.4 − 3.0 | 0.8 − 5.0 | 4.5 | 4.5 − 6.0 | |

| Max. Drying Air [m3/h] |

9.0 | 15.0 | 15.0 | 15.0 | |

| Max. Heating Power [kW] |

0.75 | 1.5 | 1.5 | 1.5 | |

| Width A [mm] |

304 | 335 | 396 | 396 | |

| Depth B [mm] |

361 | 405 | 415 | 415 | |

| Height C [mm] |

1222 | 1380 | 1115 | 1283 |

* related to COC / COP / PC / PMMA

Highlights

DD 12 "Optical Edition"

Filling level scalable:

4−12 liters

DD 24 "Optical Edition"

Filling level scalable:

6−24 liters

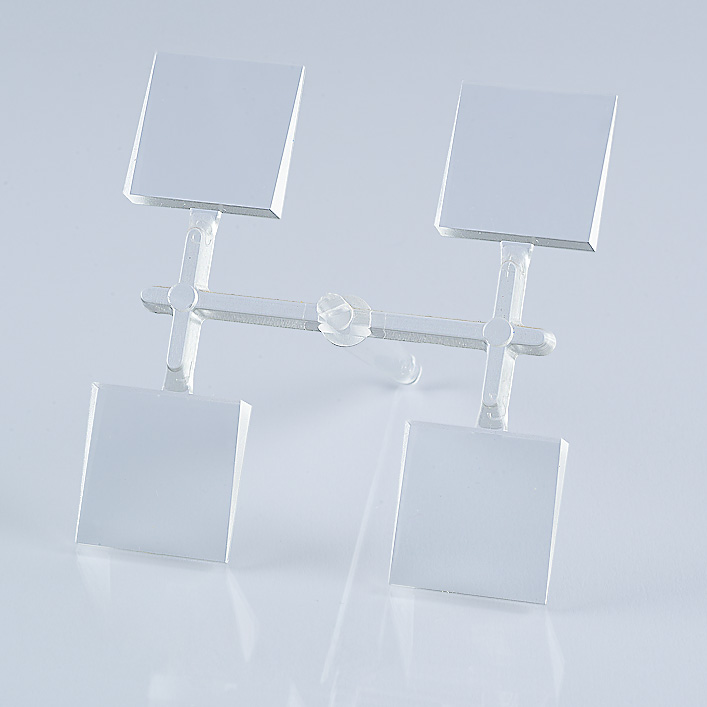

HELIO® Clean 3

For optical applications

for throughputs

up to 10 kg/h

HELIO® Clean 5

Optimised for throughputs

up to 25 kg/h

Funktion "Superclean"

Extra-long cleaning of the sifter glass by ions and optical monitoring of ion generation.

Samples

Application examples

Do you have any questions about us or our products?

Just send us a quick message and we’ll gladly get back to you via phone or mail to answer any open questions.

Customer support service by telephone

We will gladly answer all open questions.

or use your own e-mail program:

Privacy policyThe data sent will only be processed for the purpose of processing your request. You can find further information in our data protection declaration. |