Granulate deduster for plastics injection moulding

HELIO®Clean Pro

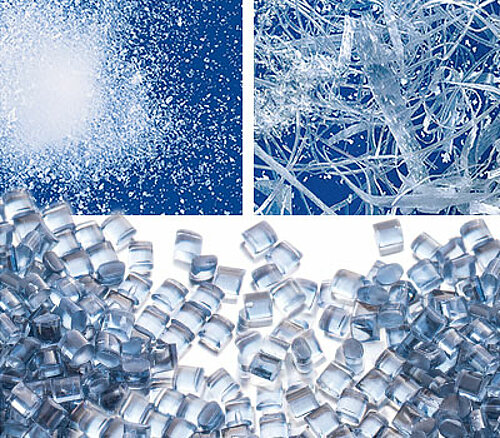

Plastic granulate and regrind dedusting before processing

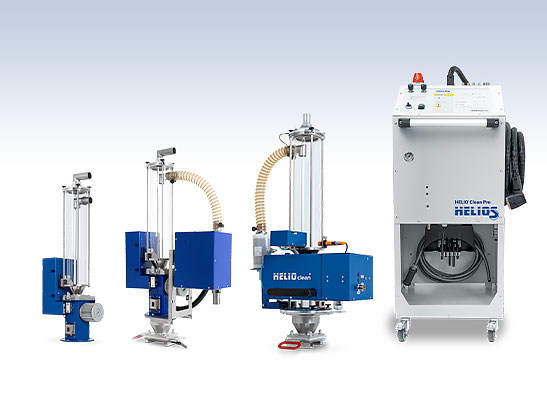

HELIO®Clean Pro Dedusting devices

Granulate cleaning before processing in plastic injection moulding

The new HELIO®Clean Pro conveying and dedusting devices are specially developed for plastics processing and are characterised by particularly gentle conveying and dedusting with an ion shower.

An integrated conveyor system sucks resin/regrind into the dedusting chamber and gently removes dust by means of air-floating with an ion shower.

- maximum dedusting degree

- gentle dedusting

- air- floating with ion-cleaning

- 2x ionizer integrated

- 4-stage dedusting process

- material throughput up to 35 kg/h*

Dedusting technology

Perfect granulate cleaning with the HELIO®Clean Pro dedusting technology

An integrated conveyor system sucks resin/regrind into the dedusting chamber. The conveying speed can be preselected steplessly and new dust formation due to abrasion can be avoided. A portion of exactly the same amount is gently dedusted by means of air-floating with an ion shower. The resin/regrind is sucked only as high that it does not touch the sieve disc at the dust outlet or leave the separator when the sieve disc is removed. Light parts such as dust or lint leave the separator at the top through the sieve disc and are separated into the dust collection container. HELIO®Clean Pro - devices without a sieve disc are even able to remove angel hair safely, which is produced when conveying plastic granulate flying.

4-stage dedusting technology

- Conveying

Pre-dedusting during filling by slow vacuum conveying.

- Loosening

Staged soft start with loosening.

- Air floating + ion shower

Gentle air- floating with ionizedair. Adjustable Fountain with laminar air flow and dust removal.

- Cleaning

Automatic cleaning and neutralization of the separator glass by ionized air betweentwo dedusting cycles and dust removal.

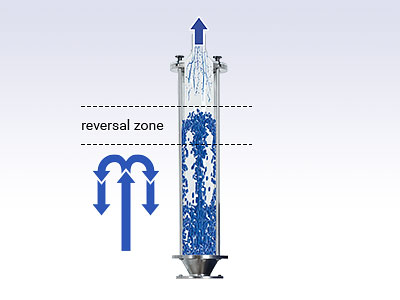

Material fountain

A laminar air stream with ionized air carries the material to be dedusted adjustable up to the upper third of the separator, where it reverses by gravity and returns to the starting point at the glass wall without leaving the open dedusting chamber (separator) at the bottom. This process is time-controlled, freely adjustable and repeats itself several times. Only after switching off the vacuum the dedusted portion is transferred to the intermediate container below.

Ion shower while whirling-up in the air fountain

While the granulate is whirled up and circulated in the deduster, a continuous stream of ionized air is blown through the portion to be dedusted. In this way, the binding forces between dust particles and granules are reduced to such an extent that the dust loosens and can be separated by air-floating. Due to the special glass construction, the ions are particularly „long-lasting“ and therefore lead to a high efficiency of the ion shower.

Special glass construction

The dedusting chamber is made of abrasion-resistant special glass. This allows efficient cleaning with the aid of ions, as these are not neutralized immediately when they hit the separator wall, but can release the binding forces between dust and material over a longer period of time. This design also enables the conveying and cleaning process to be viewed from all sides.

HELIO®Clean Pro 10

Granulate cleaning before processing in plastic injection moulding

The new HELIO®Clean Pro 10 conveying and dedusting device was specially developed for plastics processing and is characterised by particularly gentle conveying and dedusting with an ion shower.

An integrated conveyor system sucks resin/regrind into the dedusting chamber and gently dedusted by means of air-floating with an ion shower.

- maximum dedusting degree

- gentle dedusting

- control stand with cleaning aid

- compact or split construction

- 1- or 2-component version

- air- floating with ion-cleaning

- 2x ionizer integrated

- 4-stage dedusting process

- material throughput up to 35 kg/h*

* depending on material and required degree of dedusting example based on PMMA/PC

Assembly versions

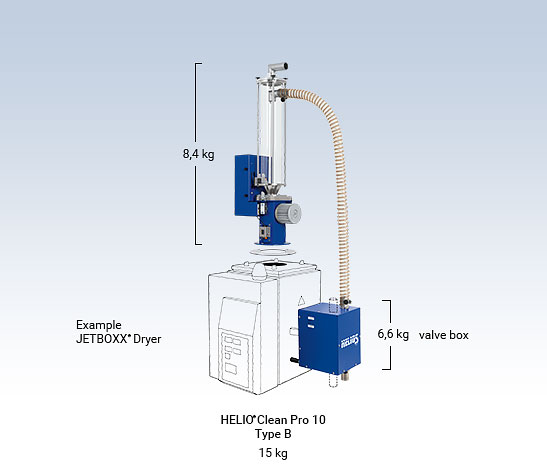

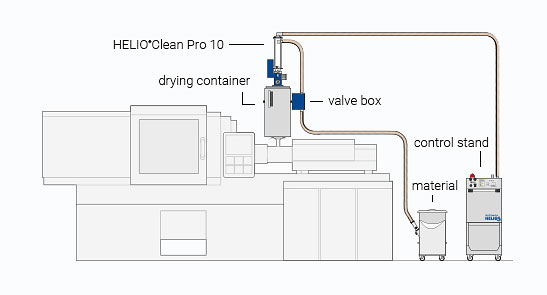

HELIO®Clean Pro 10 - Type B

Split version

Construction for mounting on drying container

Conveying and dedusting of the material on drying containers with following drying. The valve box can be easily disassembled and attached to the desired position, e.g. hooked up to the container handle.

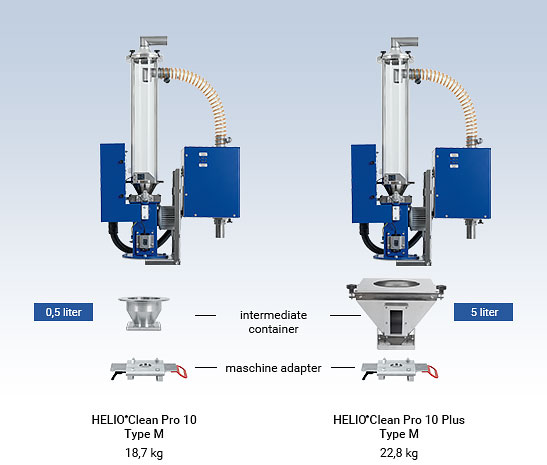

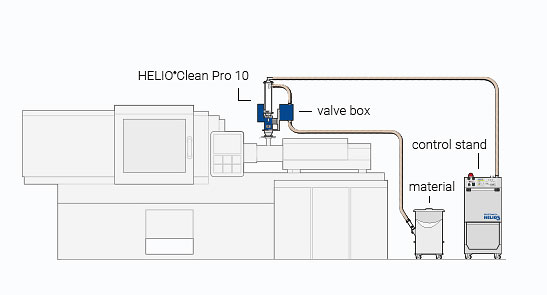

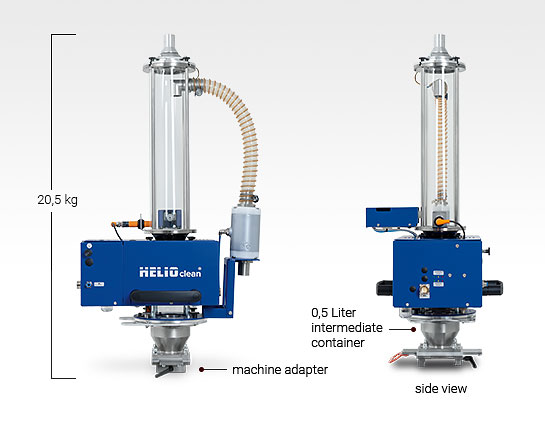

HELIO®Clean Pro 10 - Type M

Compact version

For mounting on processing machine

Conveying and dedusting of the material directly on the feeding zone of the processing machine.

HELIO®Clean Pro 10

| material throughput* | max. 35 kg/h |

| dedusting portion | 0,5 liter 0,5 - 1,2 liter type Pro 10 Plus |

| process | air-floating with ionized air by circulating in the fountain |

| ionizer | 2 Ionizers standard |

| dust removal | dust collection container integrated in control stand |

| control | HELIO®Clean Pro control stand |

| features |

|

| place of action | mounting on drying-container / processing-machine or Dedusting module |

* depending on material and required degree of dedusting example based on PMMA/PC

Standard equipment

- 1-component compact version

Type M (mounting on processing-machine) - control stand with dust collector and disconnectable control line

- version can be converted to split version

- 2 ionizers as standard

- outlet aid

- switchable vacuum cleaner for cleaning the dust collector

- suction pipe and conveyor hose PUR-H 3 m

- dust discharge hose 5 m

- machine adapter with dustproof shut-off valve and L-guides for sliding rail

Options

- intermediate container 5.0 liter for type Pro 10 Plus

- 2-component version (Mix)

- flange ring for mounting on drying container

- conveying hose PUR-H 5 m

Optional dedusting module

For integration in conveying systems of any make.

HELIO®Clean Pro 20

Granulate cleaning before processing in plastic injection moulding

The new HELIO®Clean Pro 20 is the most powerful HELIOS conveying and dedusting unit and was specially developed for plastics processing. It is characterized by particularly gentle conveying and dedusting with an ion shower and is suitable for the most difficult dedusting tasks.

- high material throughput

- gentle dedusting

- control stand with cleaning aid

- special glass construction

- or 2-component version

- air- floating with ion-cleaning

- 2x ionizer integrated

- 4-stage dedusting process

- material throughput up to 50 kg/h*

*depending on material and required degree of dedusting example based on PMMA/PC

Assembly versions Pro 20

M-version for mounting directly on processing machine

Practical example: HELIO®CLEAN Pro 20 deduster on processing machine

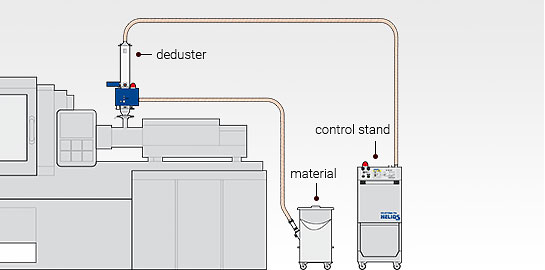

Example A

Conveying and dedusting of the material directly to the feeding zone.

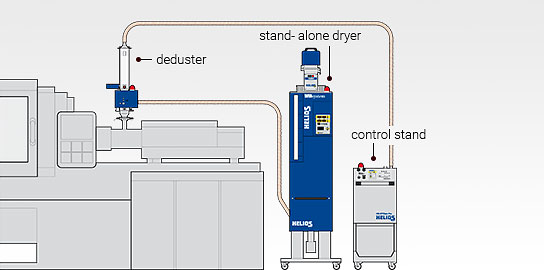

Example B

Material drying via stand-alone dryer with subsequent conveying and dedusting of the material on the feeding zone.

HELIO®Clean Pro 20

| material throughput* | max. 50 kg/h |

| dedusting portion | 0,5 liter 0,5 - 2,0 liter type Pro 20 Plus |

| process | air-floating with ionized air by circulating in the fountain |

| ionizer | 2 Ionizers standard |

| dust removal | dust collection container integrated in control stand |

| control | HELIO®Clean Pro control stand |

| features |

|

| place of action | mounting on processing machine or Dedusting module |

* depending on material and required degree of dedusting example based on PMMA/PC

Standard equipment

- 1-component version

Type M (for mounting on processing machine) - control stand with dust collector

- 2 ionizers as standard

- switchable vacuum cleaner for cleaning the dust collector

- suction pipe and conveyor hose PUR-H 3 m

- dust discharge hose 5 m

- machine adapter with dustproof shut-off valve and L-guides for sliding rail

Options

- intermediate container 5.0 liter for type Pro 20 Plus

- 2-component version (Mix)

- conveying hose PUR-H 5 m

Optional dedusting module

For integration in conveying systems of any make.

Control stand with dust collecting container - Pro 10 / 20

Equipment

- 3-stage vacuum generator

- dust collecting container

- automatic filter cleaning

- integrated cleaning aid

- system pressure regulator

- quick coupling for control line

- stepless fine adjustment for conveying and air-floating

Operation

The basic setting and the possible settings for the four functional areas are visible at the control stand. Each function key has several sub-levels which can be called up by pressing the key. Detailed operating instructions allow you to optimize the process steps for each application.

Dust collecting container

The dust collection container can be simply pulled out and emptied.

Integrated cleaning aid - easy handling - Pro 10 / 20

Use as cleaning aid

To clean the dust extractor, the control stand can be used as a classic vacuum cleaner. Instead of the dust discharge hose, the vacuum cleaner hose is plugged on and used together with one of the supplied cleaning attachments.

The dedusting chamber can be hinged down / swivelled out

The dedusting chamber can be hinged down for cleaning (Pro 10) / The upper part of the deduster can be released and swivelled out (Pro 20).

Cleaning when changing material

Do you have any questions about us or our products?

Just send us a quick message and we’ll gladly get back to you via phone or mail to answer any open questions.

Customer support service by telephone

We will gladly answer all open questions.

or use your own e-mail program:

Privacy policyThe data sent will only be processed for the purpose of processing your request. You can find further information in our data protection declaration. |