-

Big-Bag & Oktabin

OKTOMAT®|Discharging stations -

Dry-Air Technology

Plastic granulate dryer -

Granulate + Regrind

Dedusting devices - our services

- HELIOS

Deduster for plastic granulate & pellets

HELIO®Clean 3

Reliable dust removal through a 3-stage dedusting technology

Conveyor / dedusting unit with ion shower

The new HELIO®Clean 3 conveyor / dedusting unit has been specially developed for injection moulding processes with small to medium throughputs and is suitable for direct mounting on the injection unit or a drying container.

- small and powerful

- compact construction

- low weight

- air separation with ion shower

- 1- or 2-component version

- special glass construction

- simple operation

- Cleaning by means of ions

- 3-stage dedusting technology

- Optimum price/performance ratio

- Material throughput up to 25 kg/h*

*depending on material and required degree of dedusting example based on PMMA/PC

Dedusting process

Air-floating with ion shower and dust suction

3-stage dedusting technology

Conveying speed and air-floating power steplessly adjustable.

- Filling

The material is gently conveyed into the sifting glass with simultaneous dust separation already during filling.

- Air floating + ion shower

Dust separation by air-floating with ionized air with freely adjustable whirling.

- Cleaning

The sifter glass is cleaned and neutralised with ionized air between two filling processes.

Ion shower while whirling-up in the air fountain

While the granulate is whirled up and circulated in the deduster, a continuous stream of ionized air is blown through the portion to be dedusted.

In this way, the binding forces between dust particles and granules are reduced to such an extent that the dust loosens and can be separated by air-floating. Due to the special glass construction, the ions are particularly „long-lasting“ and therefore lead to a high efficiency of the ion shower.

Special glass construction

The dedusting chamber is made of abrasion-resistant special glass. This enables efficient cleaning with the aid of ions, as these are not neutralised immediately when they hit the sifter wall, but can release the binding forces between dust and granules over a longer period of time. This design also enables the conveying and cleaning process to be viewed from all sides.

Assembly versions

HELIO®Clean 3 Type M

Mounting on processing machine

HELIO®Clean 3 on injection unit. Conveying and dedusting of the material directly on the feeding zone. Intermediate container with 0.5 liter volume. Machine adapter with L-claw.

Standard equipment

- Version for mounting on processing machine with intermediate container 0,5 liter and machine adapter

- 1-component version

- Compact version (control on the unit)

- 3 m conveying hose set with venturi suction lance

- Dust collection container + 5 m dust removal hose

- Special glass, abrasion-resistant and viewable from all sides

Options

- 2-component design HELIO®Clean 3 MIX

- Split version (control unit can be mounted separately)

- Conveying hose set long (5 m)

- Dust collection container extension

(+11 liter volume) - Sifting glass extension +100mm

| material throughput | max. 25 kg/h* |

| dedusting portion | 0,38 - 0,5 liter |

| process | air-floating with whirling up by ionized compressed air from below |

| ionizer | 1 ionizer standard |

| dust removal | separate dust collection container |

| control | HELIO®Clean 3 control |

| features |

|

| place of action | mounting on processing machine or Dedusting module |

* depending on material and required degree of dedusting example based on PMMA/PC

HELIO®Clean 3 Type B

Mounting on drying container with portioner

JETBOXX® dryer with HELIO®Clean 3. Conveying with dedusting of the material directly to drying container or intermediate container 0,5/2,0/5,0 liter. The HELIOS portioning device provides a reproducible, always the same dust separation portion with controlled transfer to a downstream (drying) container.

Standard equipment

- Version with portioner for mounting on container

- Adapter flange ring

- 1-component version

- Compact version (control on the unit)

- 3 m conveying hose set with venturi suction lance

- Dust collection container + 5 m dust removal hose

- Special glass, abrasion-resistant and viewable from all sides

Options

- 2-component design HELIO®Clean 3 MIX

- Split version (control unit can be mounted separately)

- Conveying hose set long (5 m)

- Dust collection container extension

(+11 liter volume) - Sifting glass elevation +100mm

- Intermediate container 0,5 / 2,0 / 5,0 liter

| material throughput | max. 25 kg/h* |

| dedusting portion | 0,38 - 0,5 liter |

| process | air-floating with whirling up by ionized compressed air from below |

| ionizer | 1 ionizer standard |

| dust removal | separate dust collection container |

| control | HELIO®Clean 3 control |

| features |

|

| place of action | directly on container with portioner or Dedusting module |

* depending on material and required degree of dedusting example based on PMMA/PC

Equipment

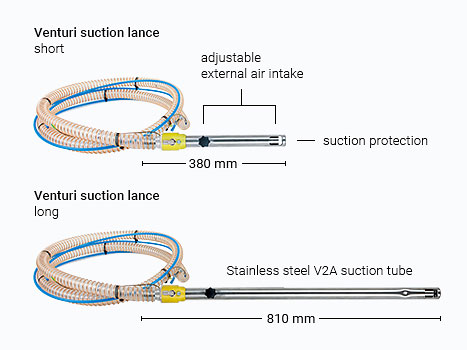

Conveying hose set

- Compressed air driven Venturi suction lance

short or long version

Conveying height up to 8 m - conveying hose

PUR-H DN 32 (3m) with earthing

compressed air line bundled with hose

Options

- conveying hose long (5 m)

Dust removal

- dust collection container

5,5 liter volume - dust removal hose

DN-50 5m

The separated dust is removed into a separate dust collection container. An integrated exhaust air filter ensures dust-free ambient air.

Options

- dust collection container extension

+ 11 litre volume

Dedusting module for conveying systems

Integration of all HELIO®Clean dedusting devices in conveying systems of any make

The existing on-site conveying equipment will remain in use - it is only moved sideways onto a sliding rail. In this new position there is a suction device under the sliding rail from which the material conveyed is sucked into the HELIOS dust separation device, the dust is removed portion by portion and then it is transferred to the processing machine.

Do you have any questions about us or our products?

Just send us a quick message and we’ll gladly get back to you via phone or mail to answer any open questions.

Customer support service by telephone

We will gladly answer all open questions.

or use your own e-mail program:

Privacy policyThe data sent will only be processed for the purpose of processing your request. You can find further information in our data protection declaration. |