Options and accessories

JETBOXX®

Extensions and options for the JETBOXX® dryer system

Compressed air conveyors for drying container filling / machine feeding

Drying containers

|

|

|

|

|

|

|

|

|

|

| 3 liters | 6 liters | 12 liters | 24 liters | 20 liters | 30 liters | 50 liters | 75 liters | 200 liters | |

| Weight [kg] | 6,7 | 9,0 | 12,0 | 14,0 | 15,5 | 19,0 | 25,3 | 35,3 | 75 |

| Height [mm] | 421 | 431 | 569 | 727 | 491 | 623 | 780 | 921 | 1826 |

| Width [mm] | 314 Liter | 314 | 358 | 335 | 413 | 413 | 420 | 433 | 600 |

| Depth [mm] * | 249 Liter | 322 | 361 | 405 | 415 | 415 | 446 | 542 | 600 |

| Lid | Swivel lid | Hinged lid | Hinged lid | Hinged lid | removable | removable | removable | removable + cleaning door | removable + cleaning door |

| Optionally | Hinged cover | Hinged cover | Hinged cover | Hinged cover | |||||

| Filling volume max. | 3 liters | 6 liters | 12 liters | 24 liters | 20 liters | 30 liters | 50 liters | 75 liters | 200 liters |

| Probe- adjustment range |

2 - 5 liters | 4 - 10 liters | 6 - 20 liters | - | 20 - 26 liters | 30 - 45 liters | 50 - 70 liters | 100 - 200 liters |

* incl. WINneo® 2 control unit

Machine adapter / Special versions

Machine adapter

Polished flat slide outlet valve

L-guides for sliding rail [mm]

| 80×15 | 80×20 | |

| 100×20 | 100×25 | |

Special sizes on request.

Dustproof version

Polished outlet slide, spring-loaded pressure pieces with a Teflon sealing disc.

Medical application

All material touching parts of

stainless steel 1.4301 (AISI 304).

Lockable

With a lockable slider.

Material outlet / suction

A-1

Outlet pipe, vertical

A-2

Outlet pipe, sloping

X-1

1-fold suction device (dead-space free) for Venturi suction lance

DN 22 | DN 32

X-2

2-fold suction device for Venturi suction lances

DN 22 | DN 32

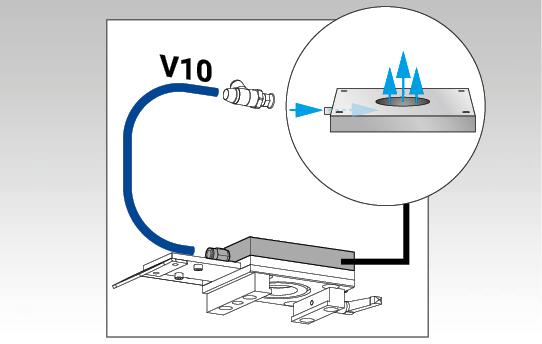

Discharge aid

While material feeding by the dosing screw, it is possible to lead compressed air shots into the outlet plate below the drying container.

XT-1 mini

mini suction device (free of dead space)

conveying line DN 22 only

integrated dry air conveying

integrated Venturi suction lance

XT-1

1-fold suction device (free of dead space) for Venturi suction lance

DN 22 | DN 32

conveying by means of dry air (optionally)

conveying by means of dry air

XT-2

2-fold suction device for Venturi suction lances

DN 22 | DN 32

conveying by means of dry air (optionally)

conveying by means of dry air

Accessories

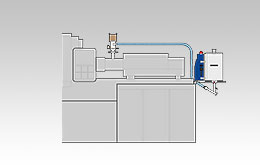

Split version

The JETBOXX® dryer control and the drying container can be mounted at appropriate places. The dry air will be led into the drying container by means of an insulated tube.

Available for 3 liters drying container size.

UP 2000

Cold regenerating adsorptions dryer

to reduce the dew point of dry air

up to −60 °C .

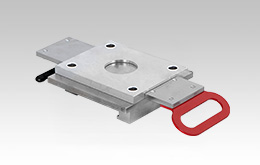

Docking plate / transport

Docking plate

Serves as a holding device for the dryer control and the docking station for changing drying containers, mounted on machine adapter.

A 20|30 liters drying container

B 3−24 liters drying container

Docking place

The docking plate with dryer control is placed directly at the injection moulding machine, for example. The drying containers are docked via a sliding rail. The dried granulate will be transported to the feeding zone by means of a suction device.

Mobile trolley

For transport from the pre-drying station to the processing point.

Sliding rail 80×15 or 80×20

Crane bracket

Stainless steel drying containers are hooked on the bracket and transported by indoor crane. Suitable for 20|30|50 liters containers

Base frames / rack

Base frames

If more than one dryer unit should be combined as stand-alone dryer or pre-dryer, 2-|3-|4-fold frames made of alumimium profile are available.

|

|

|

|

| 2-fold unit | 3-fold unit | 4-fold unit | |

| Height [mm] | 739 | 739 | 739 |

| Width [mm] | 1179 | 1679 | 2100 |

| Depth [mm] | 683 | 683 | 683 |

| Electrical power supply | Central power supply for all docking places (optionally) | ||

| Sliding rail | Sloping on both front sides, for L-shape sliding guides 80×15mm or 80×20mm | ||

Mobile base frame

When combined with a base frame, a top-mounted dryer becomes a stand-alone dryer.

Do you have any questions about us or our products?

Just send us a quick message and we’ll gladly get back to you via phone or mail to answer any open questions.

Customer support service by telephone

We will gladly answer all open questions.

or use your own e-mail program:

Privacy policyThe data sent will only be processed for the purpose of processing your request. You can find further information in our data protection declaration. |