-

Big-Bag & Oktabin

OKTOMAT®|Discharging stations -

Dry-Air Technology

Plastic granulate dryer -

Granulate + Regrind

Dedusting devices - our services

- HELIOS

Mini size plastic granulate dryer for small material quantities

JETBOXX®

Compact top-mounted plastic granulate dryer with 1 – 24 liters dryer volume

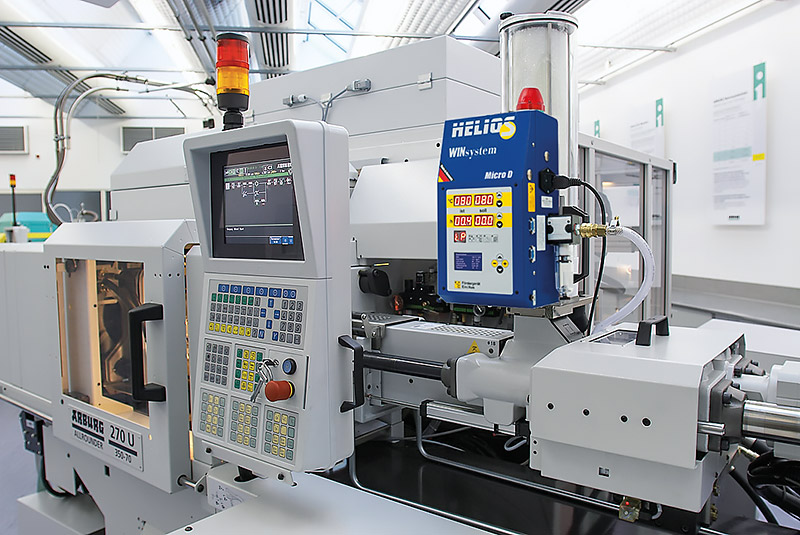

Mounting directly on the feeding zone of the processing machine

Thanks to their compact design, the plastic granulate dryer can be easily mounted on the feeding zone of the injection moulding machine. The dried material flows directly from the dryer in the plasticizing cylinder, without re-humidification or cooling. The JETBOXX® plastic pellet dryers are used in particular where small quantities of material with highest drying precision are required.

- Minimal space requirement

- Material throughput rates 0,2 – 4,8 kg/h

JETBOXX® mini dryer set

1 liter

Example: manual filling

*for PC with an average drying time of 3 h

JETBOXX® mini dryer set

2,5 liters

Example: + hopper loader with dedusting

throughput: up to 0,5 kg|h *

JETBOXX® mini dryer set

6 liters

Example: manual filling

JETBOXX® mini dryer set

12 liters

Example: hopper loader with exhaust air filter

throughput: up to 2,4 kg|h

JETBOXX® mini dryer set

24 liters

Example: 2-component hopper loader (mix) with exhaust air filter

throughput: up to 4,8 kg|h *

Drying containers / conveying technology

Drying containers

Glass- or stainless steel. Balanced distribution of the compressed air guarantees, that your material is dry and homogeneous at the right temperature.

| 1 liter | 2,5 liters | 6 liters | 12 liters | 24 liters | |

| Weight [kg] | 5,0 | 6,7 | 9,0 | 12,0 | 14,0 |

| Height* [mm] | 421 | 421 | 569 | 610 | 727 |

Filling

- Compressed air conveyors with exhaust air filter

- Compressed air conveyors with dedusting

- Manual filling

The drying containers can be opened easily on top for filling or cleaning. Glass containers have a swivelling cover, 6/12/24 liter containers have a hinged cover.

Matching compressed air conveying devices for all JETBOXX® dryers

The control unit can be removed without tools

The control can be removed from the drying container easily by means of clamping locks. For the time of service like recalibration, a dryer control in replacement will be provided by HELIOS.

Double-walled special glass

The whole inner body of the drying container consists of one single piece of special glass and is shaped conically at the outlet. A cushion of air is created by assembling with the outer glass, that functions according to the principle of a thermos flask. This is how you save energy. Another advantage of the glass construction is the all side transparent visibility into the drying container. Contaminations are immediately apparent when changing the material.

Air input - distribution

Balanced distribution guarantees, that your material is dry and homogeneous at the right temperature. The conically shaped inner glass forces the inrushing dry air through the material output and ensures, that the granule already at the machine feeding zone is kept at the right temperature. A constant flow stabilizer made of stainless steel distributes the dry air flowing upwards across the entire cross section of the cylindrical container and avoids, that the material flows too quickly through the container center. For cleaning purposes the stabilizer can be removed manually without tools.

Split version

For particularly difficult space conditions the drying control and the drying container can be arranged separately as convenient. The dry air is led into the container by an insulated hose (max. 1m). The heating control regards occurring heat losses of the hose connection.

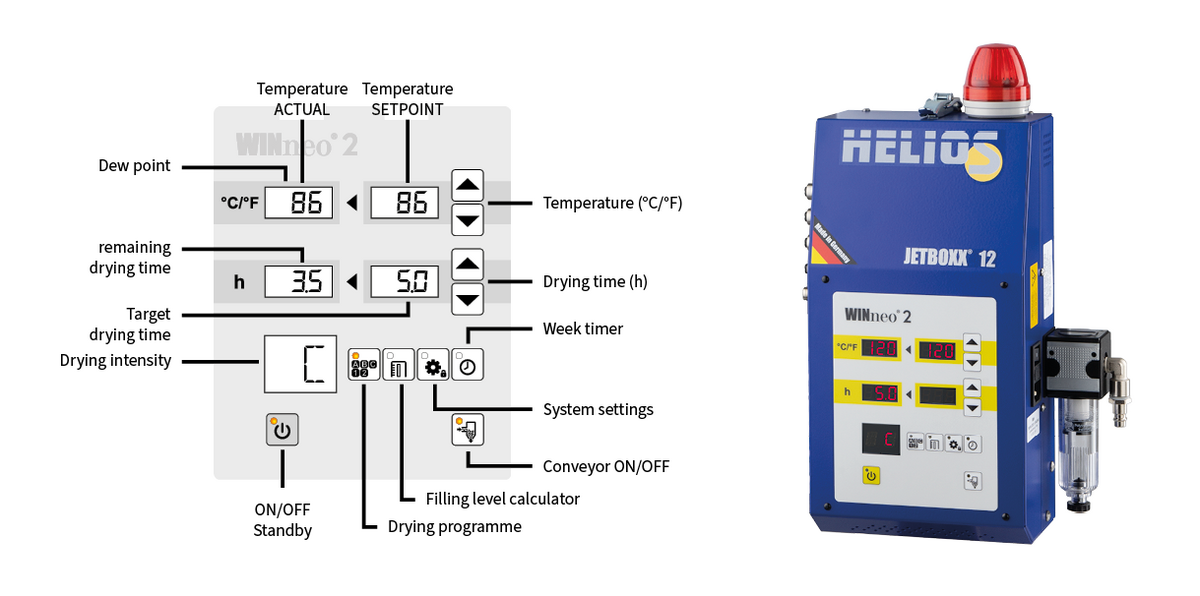

JETBOXX® control

Perfect drying result thanks to adjustable drying intensity

100% accurate repeat settings of all drying parameters.

- Drying programs

- Conveying control

- Overdrying protection

- Week timer

- Dew point measurement

- Quick dial of drying programs

Calibration service

Dryer calibration as standard

All HELIOS dryers are factory calibrated and delivered with a calibration certificate.

Repeat calibrations

are possible at the HELIOS plant.

Long-term warranty for all* dryers regarding

- Maintenance

- Repeat calibration

- Availability of interim devices

*for all JETBOXX® dryers built since 1998

After Sales Service

Our service department is of course available to provide you with expert advice throughout of the entire service life of the device.

Calibrations, maintenance and repairs are carried out at HELIOS or at site.

This is what you can expect from a good supplier.

- consulting

- commissioning

- training

- interims devices

- dryer calibration

- spare parts leaving within 48h

Do you have any questions about us or our products?

Just send us a quick message and we’ll gladly get back to you via phone or mail to answer any open questions.

Customer support service by telephone

We will gladly answer all open questions.

or use your own e-mail program:

Privacy policyThe data sent will only be processed for the purpose of processing your request. You can find further information in our data protection declaration. |