Dedusting module for conveying systems

HELIO®Clean

Integration of all HELIO®Clean dedusting devices in conveying systems of any make

Suitable for existing conveying systems of any make

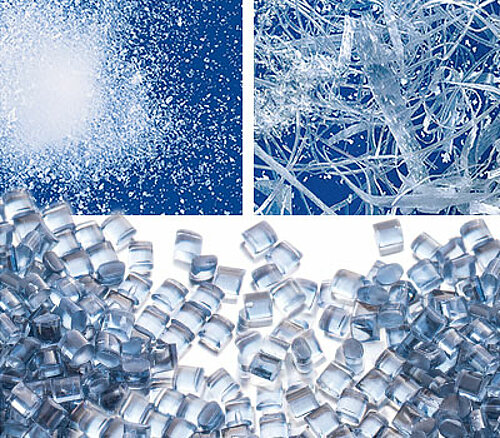

The HELIOS dedusting module is an outstanding new development which can be fitted to existing conveying systems regardless of the manufacturer. When supplying material, abrasion occurs depending on the length of the conveying distance and the number of diverte pipes. This abrasion in the form of dust or angel hair may result in serious problems at the feeder area of the processing machine or the end product. The innovative HELIOS dedusting module steps in precisely where real problems exist and therefore where there is need to take action.

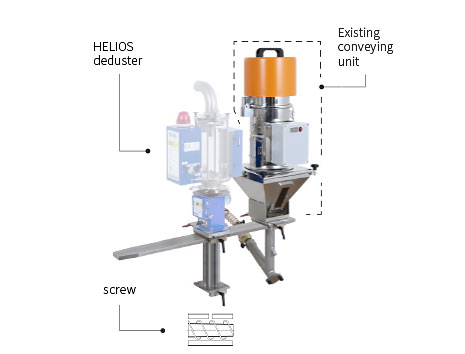

The existing on-site conveying equipment will remain in use - it is only moved sideways onto a sliding rail. In this new position there is a suction device under the sliding rail from which the material conveyed is sucked into the HELIOS dust separation device, the dust is removed portion by portion and then it is transferred to the processing machine (type A).

If the processor does not need dust removal on this conveyor at times, the HELIOS deduster can be moved to a park position and the conveying equipment is moved to the original position again via the feeder area. The conveyed material then flows again without detour into the processing machine.

- The upgrade kit is suitable for any conveying equipment available

- For HELIO®Clean 3 and HELIO®Clean Pro Series

- Material throughput up to 50 kg/h*

- Plug-and-Play

*depending on material and required degree of dedusting – example based on PMMA/PC

Upgrade kit

HELIOS dedusters remove dust by using a patented, 3 stage process by separating the air with an ion shower.

There are 3 ranges of dust separators for material flow rates of up to 25/35 kg/h* or up to 50 kg/h* for each conveying point available.

The upgrade kit, consisting of a sliding rail with an adapter for fixing it to the processing machine and suction device for the HELIOS deduster of the series:

- HELIO®Clean 3

- HELIO®Clean Pro

is suitable for any conveying equipment available.

Option: 5-litre intermediate container for on-site conveyor.

*depending on material and required degree of dedusting - Example based on PMMA/PC

Type overview

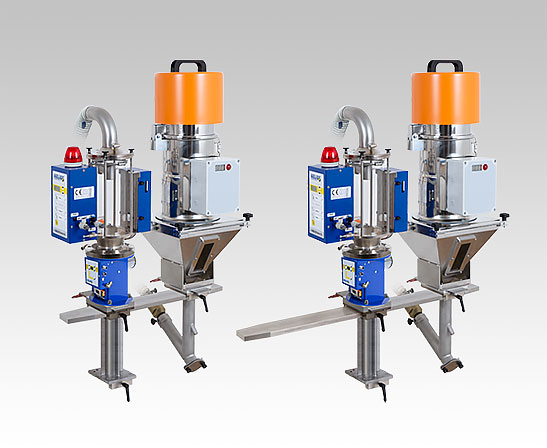

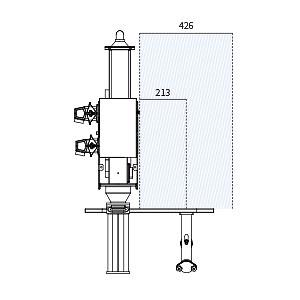

Dedusting module type A

without parking possibility for the deduster

Continuing dedusting: the dedusting module type A 1 / type A 2 is a compact upgrade set that supplements the existing conveying system with a permanently installed dedusting solution. Type A 2 offers a longer distance to the deduster.

Dedusting module type B

with parking possibility for deduster in case of non-use

Maximum flexibility: With the type B dedusting module, the deduster can be moved to the parking position by sliding it sideways. This allows the production to be switched from the dedusted material to non-dedusted material without retooling of the machine.

Function type B

Type B working position:

HELIOS deduster sucks material from suction device under the conveying device and leads the dedusted material directly to the feed zone.

Type B parking position:

Deduster is in parking position. At site existing conveying unit transfers the material directly back to the processing machine.

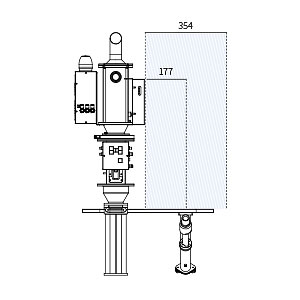

Space for conveying unit

Dedusting module type A 1 with HELIOS deduster HELIO®Clean 3.

material throughput up to 25 kg/h*

Dedusting module type A 1 with HELIOS deduster HELIO®Clean Pro 10.

material throughput up to 35 kg/h*

Dedusting module type A 2 with HELIOS deduster HELIO®Clean Pro 20.

material throughput up to 50 kg/h*

*depending on the material to be dedusted and the degree of dedustingrequired - example based on PMMA/PC

Do you have any questions about us or our products?

Just send us a quick message and we’ll gladly get back to you via phone or mail to answer any open questions.

Customer support service by telephone

We will gladly answer all open questions.

or use your own e-mail program:

Privacy policyThe data sent will only be processed for the purpose of processing your request. You can find further information in our data protection declaration. |