System components - Options - Accessories

OKTOMAT®

Components and extensions of the OKTOMAT® discharging system

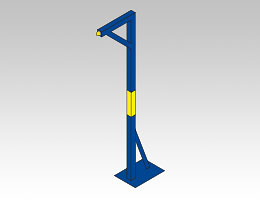

Base frames

Pedestal version

OKTOMAT® ECO

Pedestal version

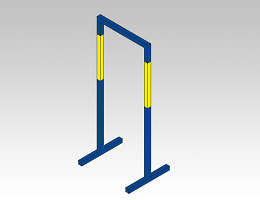

OKTOMAT® SOS

Portal Version

OKTOMAT® ECO Classic

OKTOMAT® SOS Classic

Pedestal version INOX

OKTOMAT® SOS INOX

Portal version INOX

OKTOMAT® SOS Classic INOX

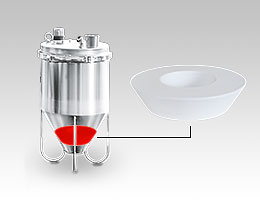

Vibrating suction heads

|

|

|

|

|

|

|

| Type | S | SM | XL | S-80 C | XL-80 C | SM-AK C |

| Ø Conveying hose | 38/45/50 mm | 38/45/50/60/65/80 mm | 38/45/50/60/65/80 mm | 38/50/65/80 mm | 38/50/65/80 mm | 38/50/65/80 mm |

| Ø diameter | 295 mm | 295 mm | 495 mm | 250 mm | 450 mm | 250 mm |

| Material | 1.4301 | 1.4301 | 1.4301 | 1.4404/1.4571 AISI 316L/ 316TI | 1.4404/1.4571 AISI 316L/ 316TI | 1.4404/1.4571 AISI 316L/ 316TI |

| Vibrator electric 230V | ||||||

| Vibrator electric 110V | ||||||

| Vibrator pneumatic | ||||||

| Fluidization | ||||||

| ATEX | ||||||

| Suction basket | ||||||

| Slash/dead space free |

standard

optional

not available

Foil / bag tightener

|

|

|

|

|

|

|

| Type | FBB 260 | FBB 400 | FBB 600 | F-Segment 600 | BB 160 | BB 500 |

| Use | foil / big bag tightener | foil / big bag tightener | foil / big bag tightener | foil tightener | big bag tightener | big bag tightener |

| Diameter | 260 mm | 400 mm | 600 mm | 600 mm | 160 mm | 500 mm |

| Fixation | lashing strap + carabiner | lashing strap + carabiner | lashing strap + carabiner | clamping jaws | carabiner | carabiner |

| ATEX |

optional

not available

Optional functions

Fluidization

For loosening up compacted bulk material, compressed air can be injected to fluidize the material to be sucked off.

- available for suction head SM-80 and XL-80 only

- separate control with two independent pneumatic circuits

OKTOMAT® SOS OKTOMAT® SOS Classic

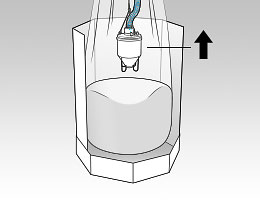

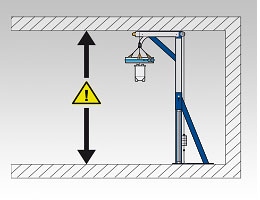

Emptying

In order to be able to empty the pipeline after each conveying process (e. g. in the case of long rising pipes), the suction head is raised above the bulk material level in the container when a signal is received from a conveyor control system and the pipeline is emptied.

OKTOMAT® SOS OKTOMAT® SOS Classic

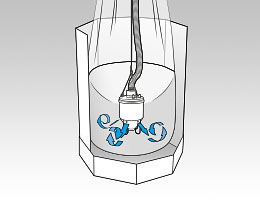

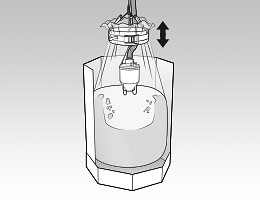

Oscillating system for suction head

The suction head enters vibrating into the material, is pulled up again in a time-controlled manner (the resulting sinkhole in the material fills up), is then lowered back onto the surface and the procedure starts again. The oscillation, stroke, lifting force and sequence of short or long strokes are individually adjustable.

OKTOMAT® SOS OKTOMAT® SOS Classic

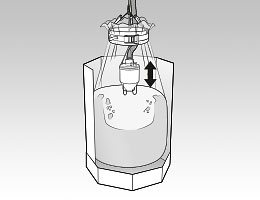

Oscillating system for foil / big bag tightener

In case of very bridging materials, a non-slip wall may occur during the suction process. By repeated lowering and lifting of the foil / big bag tightener during suction, the material wall will be loosened, thus enabling the material to flow towards the suction point.

OKTOMAT® SOS OKTOMAT® SOS Classic

Installation

Elevation base for pedestal version

Base element to increase height by 300 mm. Mounting on OKTOMAT® foot section.

- Height: 300 mm

- Weight: 64 kg

OKTOMAT® ECO OKTOMAT® SOS

Movable frame for pedestal version

Movable frame on 4 castors incl. fixing bolts.

Suitable for continuous use.

OKTOMAT® ECO OKTOMAT® SOS

Movable frame for portal version

Movable frame on 4 castors incl. fixing bolts.

Suitable for continuous use.

OKTOMAT® ECO Classic

OKTOMAT® SOS Classic

Movable frame for INOX pedestal version

version in stainless steel design for OKTOMAT® SOS INOX

movable frame on 4 castors incl. fixing bolts

Suitable for continuous use

OKTOMAT® SOS INOX

Accessories

Remote control

Lifting and lowering of suction head and foil/bag tightener

- 5 m cable

OKTOMAT® SOS

Pipe elbows

DN38, DN45 and DN50 (outer diameter)

- Standard pipe elbow

material stainless steel 1.4301 - Stainless steel pipe elbow (hardened) wear-resistant

- Glass pipe elbow highly wear-resistant

for all OKTOMAT® types

Additional weight

The additional weight increases the contact weight of the suction head on the bulk material and thus helps to enter into the bulk material.

- available for suction head S38 / S45 / S50 only

- + 4 kg bearing weight

Cantilever arm

If filling into another container is carried out directly at the emptying point, a hopper loader with an outlet valve can be installed when using a cantilever arm. Different mounting options for the hopper loader are available.

for all OKTOMAT® types

Enshrouding with dry air

Breaks in production with open containers are a quality risk for the bulk material: it threatens to remoisten. Dry air circulation / coating impedes moisture absorption from the ambient air. Dry air is blown into the container via the suction head and the moist ambient air is displaced.

Protection cover

Ø 1200 mm / Ø 1600 mm

Cover for containers + foil/big bag tightener

PVC, transparent with zipper

for all OKTOMAT® types

Not suitable for ATEX applications!

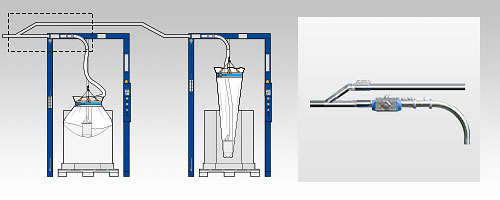

Systems

Double station

As soon as an empty signal is received from the ECO / SOS / OKTOBAG control, the conveying is switched on to the next full container via pneumatic ball valves.

- Any number of OKTOMAT® stations can be combined.

- Ideal for unmanned shifts

suitable for all OKTOMAT® types

suitable for all OKTOMAT® types

Vacuum conveying technology - HELIO®Vac

Suitable conveying technology for the OKTOMAT® discharge system.

Special sizes

Extension ECO

Using an extended middle section you can achieve assembly height of 3500 - 3900 mm (4 x 100 mm steps). Rope and cable lengths must be adjusted.

OKTOMAT® ECO

Extension for Classic version

Extension 600 mm for maximum installation height of 4270 mm.

OKTOMAT® ECO Classic

OKTOMAT® SOS Classic

Widening for Classic version

Extension 300 mm for maximum portal width of 1820 mm.

for extra wide containers, max. width of container 1500 mm.

OKTOMAT® ECO Classic

OKTOMAT® SOS Classic

Customer-specific special height

Special construction for low room height and low containers. 2500 to 3000 mm (4 x 125 mm steps).

OKTOMAT® ECO

Controls

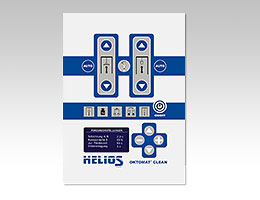

ECO control

- Adjustable residual discharge time

- Empty signal with potential-free contact

- Automatic switching with double station

OKTOMAT® ECO

SOS control

- Adjustable residual discharge time

- Empty signal with potential-free contact

- Automatic switching with double station

- Oscillating system for suction head and foil / big bag tightener

- Automatic operation / manual operation

OKTOMAT® SOS

SOS INOX control

- SOS control in stainless steel housing

- Adjustable residual discharge time

- Empty signal with potential-free contact

- Automatic switching with double station

- Oscillating system for suction head and foil / big bag tightener

- Automatic operation / manual operation

OKTOMAT® SOS INOX

OKTABAG control

- 8 function keys

- Graphic display with intuitive operator guidance

- Display of all operating states

- Buttons for automatic operation

- Button for conveyor unit ON/OFF

OKTOMAT® SOS

Do you have any questions about us or our products?

Just send us a quick message and we’ll gladly get back to you via phone or mail to answer any open questions.

Customer support service by telephone

We will gladly answer all open questions.

or use your own e-mail program:

Privacy policyThe data sent will only be processed for the purpose of processing your request. You can find further information in our data protection declaration. |