Compressed air conveyors

JETBOXX®

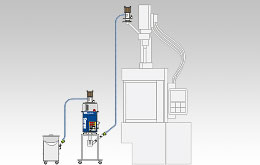

Suitable conveyor technology for the JETBOXX® dryer system

conveyors with exhaust air filter

OPTION C Micro

- 1-component conveyor

- Special glass and stainless steel

- Capacitive filling level sensor

- For 3 liters containers

- Conveying pipe DN 32

- Mounting on glass drying container

OPTION C Mini

- 1-component conveyor

- Special glass and stainless steel

- Capacitive filling level sensor

- For 6|12 liters containers

- Conveying pipe DN 32

- Mounting on drying container

OPTION C

- 1-component conveyor

- Special glass and stainless steel

- Capacitive filling level sensor

- For 20|24|30|50|75 liters containers

- Conveying pipe DN 32

- Mounting on drying container

OPTION C-M

- 1-component conveyor

- Special glass and aluminium/stainless steel

- Capacitive filling level sensor

- Machine adapter with gate valve

- Conveying pipe DN 32

- Mounting on processing machine

Control by JETBOXX® dryers

JETBOXX® dryers from HELIOS can control up to two compressed air conveying units. All parameters for conveying can be set directly on the dryer system control.

More information

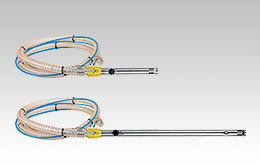

Conveying set DN 22 | DN 32

Compressed air conveying Venturi principle

- Conveying hose set

PUR hose + compressed air line

(3m or 5m) - Suction lance

Venturi suction lance

(short 380mm / long 810mm)

Conveying height up to 6m

Because of their construction, HELIOS compressed air conveyors are able to convey the material gently up to 6m.

Conveyors with exhaust air filter and separate control

HELIO®Jet 2-M

1-component conveyor

with exhaust air filter

- of special glass + stainless steel

- with individual control

- compact or split version

- conveying line DN 32

HELIO®Clean 2-M

1 or 2 components conveyor

with dedusting

- of special glass + stainless steel

- with individual control

- compact or split version

- conveying line DN 32

More Information

HCA 1

compressed air driven suction conveyor with exhaust air filter for 1 component.

- with individual control

- compact or split version

- conveying line DN 40

Optionally

- intermediate container 5 liters

- mixing valve for 2nd component

HCA 2

compressed air driven suction conveyor with exhaust air filter for 1 or 2 components

- with individual control

- compact or split version

- conveying line DN40

Optionally

- intermediate container 5 liters

- mixing valve for 2nd component

Conveyors with dedusting without individual control

OPTION CE Mini

- 1-component conveyor

- With dedusting

- Special glass and stainless steel

- Capacitive filling level sensor

- For 3|6|12 liters containers

- Conveying pipe DN 32

- Mounting on drying container

OPTION CE

- 1-component conveyor

- With dedusting

- Special glass and stainless steel

- Capacitive filling level sensor

- For 20|24|30|50|75 liters containers

- Conveying pipe DN 32

- Mounting on drying container

OPTION ME

- 2-components conveyor

- With dedusting

- Special glass and stainless steel

- Capacitive filling level sensor

- For 20|24|30|50|75 liters containers

- Conveying pipe DN 32

- Mounting on drying container

OPTION CE-M

- 1 or 2-component conveyor

- With dedusting

- Special glass and stainless steel / aluminium nickel-plated

- Machine adapter with gate valve

- Capacitive filling level sensor

- Conveying pipe DN 32

- Mounting on processing machine

Control by JETBOXX® dryers

JETBOXX® dryers from HELIOS can control up to two HELIO®Clean 2 dedusting units. All parameters for drying and dedusting can be set directly on the dryer control unit.

More information

Conveying set DN 32

Compressed air suction lance consisting of

- Conveying hose set

PUR H-hose + compressed air line

with copper spiral (earthing)

(3m standard - optional 5m) - Suction lance

Venturi suction lance

(short 380mm / long 810mm)

Dust separation

consisting of

- Dust discharge hose

DN-50 5m - Dust collecting container

Volume 5,5 liter

Optionally

- expansion to 11 liter

Compressed air conveyors with dedusting and control

The HELIO®Clean 2 conveyor / dedusting unit was specially developed for injection moulding and is suitable for mounting on a processing machine or a drying container.

- 1 or 2 components version

- machine-version M-type or container-version B-type

- easy operation

- special glass construction

- material throughput up to 25 kg/h*

*depending on material and required degree of dedusting

Do you have any questions about us or our products?

Just send us a quick message and we’ll gladly get back to you via phone or mail to answer any open questions.

Customer support service by telephone

We will gladly answer all open questions.

or use your own e-mail program:

Privacy policyThe data sent will only be processed for the purpose of processing your request. You can find further information in our data protection declaration. |