-

Big-Bag & Oktabin

OKTOMAT®|Discharging stations -

Dry-Air Technology

Plastic granulate dryer -

Granulate + Regrind

Dedusting devices - our services

- HELIOS

Mobile plastic granulate dryers

JETBOXX®

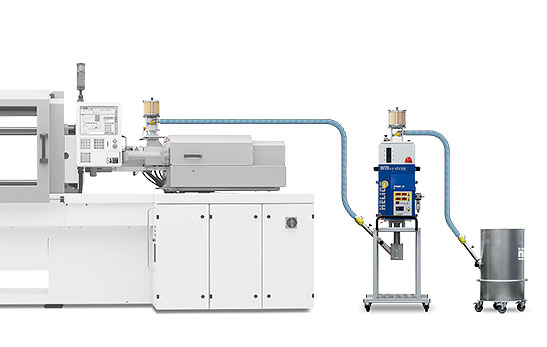

Stand-alone dryer placed next to the processing machine

Positioned next to the processing machine, with material conveying to the feeding zone

JETBOXX® mobile plastic granulate dryers (stand-alone) can be used wherever top-mounted dryers fail for weight / or placement reasons. Installation of the system components on a base frame for drying before/during processing with conveying of the dried granules to the injection unit.

If the task changes, the system components can simply be exchanged or used as top-mounted dryers, for example.

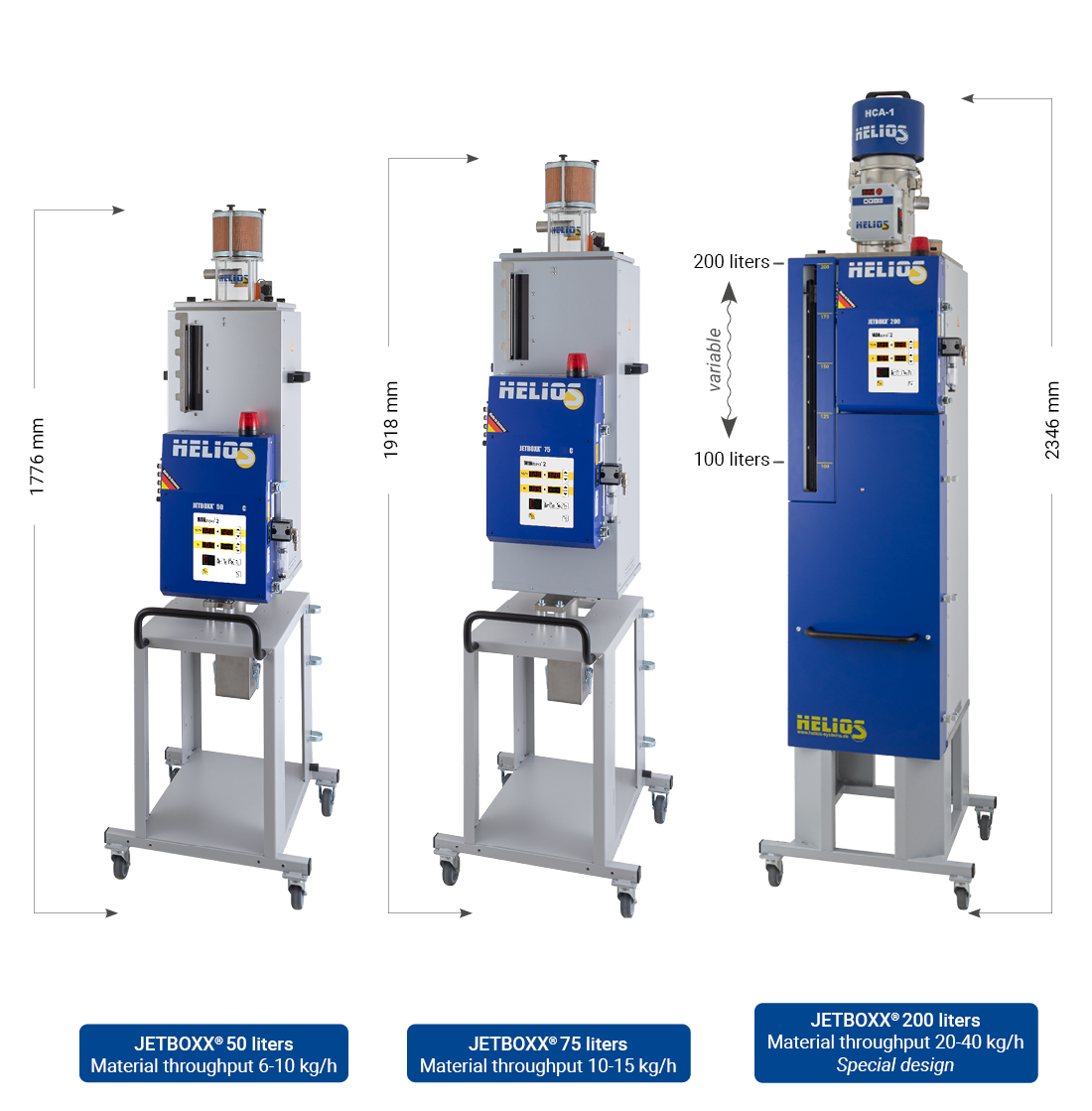

Minimal space requirement

Stand - alone dryer frame: 510 x 490 mm, special design JETBOXX® 200: 600 x 600 mm

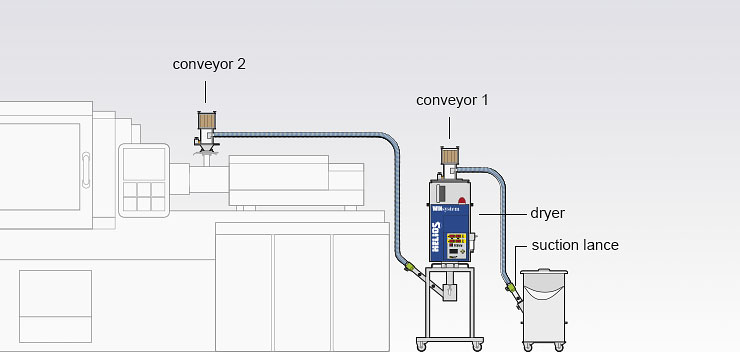

Installation variants

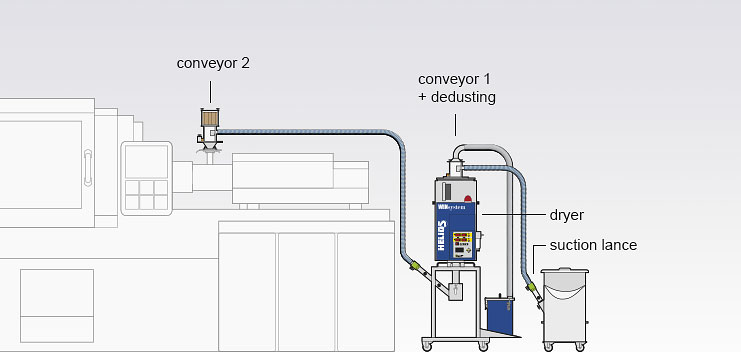

A variant

Conveying and drying of one component directly next to the injection molding machine. Conveying of the dried material to the feeding zone. Conveying height up to 8m possible. Selectable with/without dry air conveying.

B variant

Conveying, dedusting and drying of one component next to the injection molding machine. Conveying of the dried material to the feeding zone. Selectable with/without conveying with dried air.

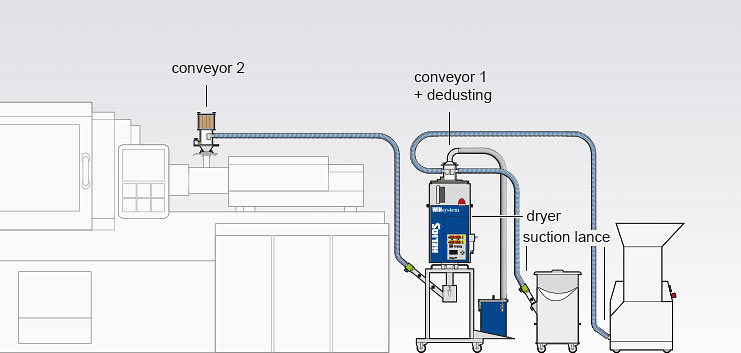

C variant

Conveying, dedusting and drying of two components (virgin/regrind material) next to the injection molding machine. Conveying of the dried material to the feeding zone. Selectable with/without conveying with dried air.

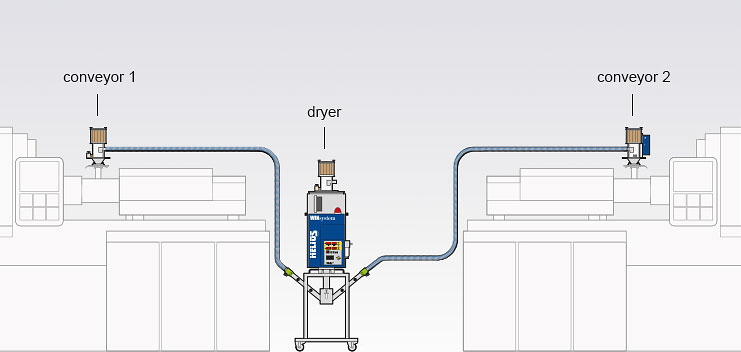

D variant

Example: Feeding of two machines with dried material. Selectable with/without conveying with dried air.

Conveying to the feeding zone

The conveyor control is included in the JETBOXX® dryer control unit

Due to their construction, the HELIOS compressed air conveyors are capable of gently conveying of material up to a height of 8 m.

Depending on the hygroscopicity of the dried granulate/regrind material, it is possible to use ambient or dried air at the drying container outlet box for conveying to the feeding zone.

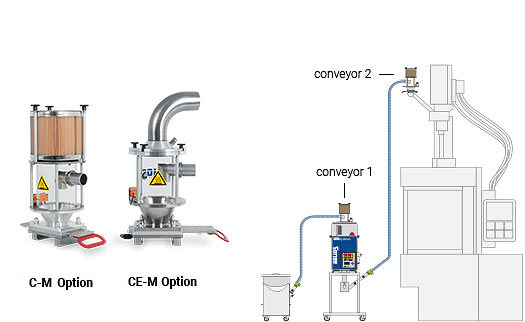

There are conveyers for 1 or 2 components available, optionally with or without dedusting function.

Suction devices

Suction devices with conveying with dry air

3 new types of suction devices allow a 100 percent avoidance of moisture adsorption of the dried material anew in the waiting or conveying phase.

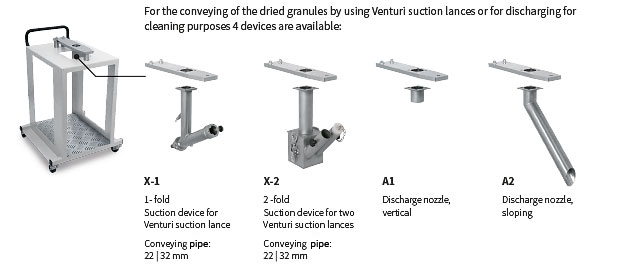

Suction / discharge devices

For the conveying of the dried granules by using Venturi suction lances or for discharging for cleaning purposes 4 devices are available.

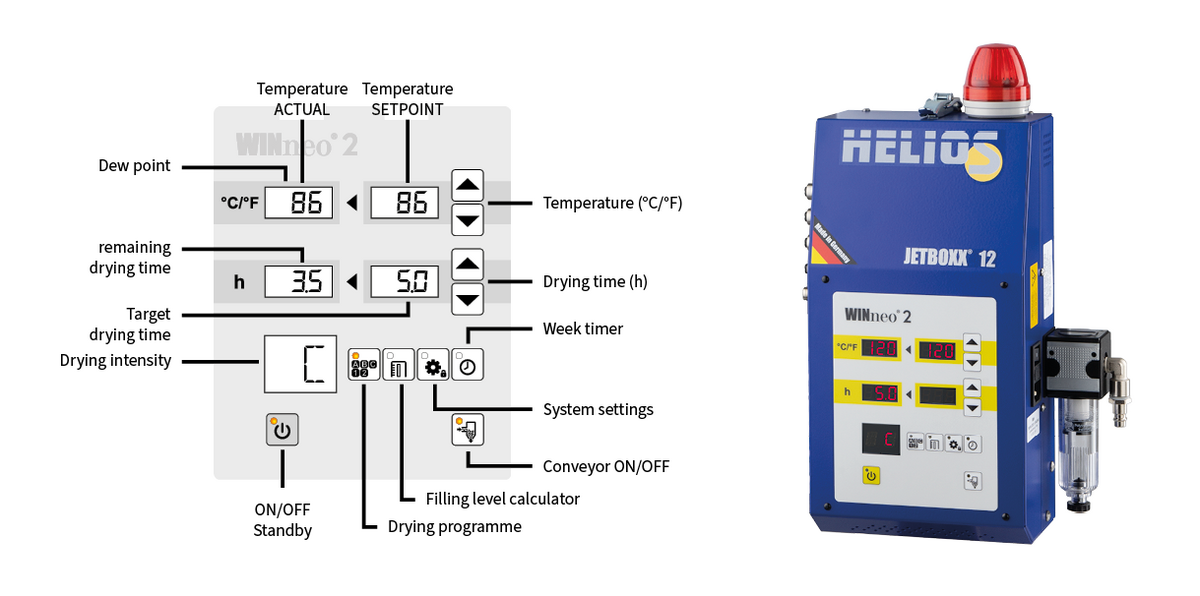

JETBOXX® control

Perfect drying result thanks to adjustable drying intensity

100% accurate repeat settings of all drying parameters.

- Drying programs

- Conveying control

- Overdrying protection

- Week timer

- Dew point measurement

- Quick dial of drying programs

Calibration service

Dryer calibration as standard

All HELIOS dryers are factory calibrated and delivered with a calibration certificate.

Repeat calibrations

are possible at the HELIOS plant.

Long-term warranty for all* dryers regarding

- Maintenance

- Repeat calibration

- Availability of interim devices

*for all JETBOXX® dryers built since 1998

After Sales Service

Our service department is of course available to provide you with expert advice throughout of the entire service life of the device.

Calibrations, maintenance and repairs are carried out at HELIOS or at site.

This is what you can expect from a good supplier.

- consulting

- commissioning

- training

- interims devices

- dryer calibration

- spare parts leaving within 48h

Do you have any questions about us or our products?

Just send us a quick message and we’ll gladly get back to you via phone or mail to answer any open questions.

Customer support service by telephone

We will gladly answer all open questions.

or use your own e-mail program:

Privacy policyThe data sent will only be processed for the purpose of processing your request. You can find further information in our data protection declaration. |