-

Big-Bag & Oktabin

OKTOMAT®|Discharging stations -

Dry-Air Technology

Plastic granulate dryer -

Granulate + Regrind

Dedusting devices - our services

- HELIOS

Emptying stations for Octabin and Big Bag

OKTOMAT® ECO

The basic emptying station for the most common bulk materials

Emptying system with vibrating suction head and automatic bag tightener

The OKTOMAT® ECO Series handles easily and effectively the emptying of all common types of big bags, octabins, folding boxes, lattice boxes, bulk bags with foil inlet, etc. Simply use a pallet jack to move the bulk bags, clamp the foil and the suction will follow without supervision and risk of interruption. The bulk bags will be completely emptied.

- Automatic complete emptying

- Automatic foil / big bag tightener

- Vibrating suction head

OKTOMAT® System

- easy to operate

- unmanned operation

- minimal operating costs

- low maintenance

- robust and durable

- just pallet jack will do

- proven in thousands

OKTOMAT® ECO Series

Fitted as standard with all the basic functions of the OKTOMAT® system.

Equipment

- optical display of the residual discharge phase

- automatic complete emptying

- vibrating suction head

- automatic foil-/ big bag tightener

- pedestal or portal version

- residual discharge time (ECO control) optional

Materials

OKTOMAT® ECO is ideally suited for the majority of applications. It handles the emptying of free-flowing to poorly flowable materials. For more difficult tasks, the discharge station can be extended with options.

Types of bulk bags

Applicable for all bulk bag types

The OKTOMAT® handles easily and effectively the emptying of all common types of Big Bags, octobins, folding boxes, lattice boxes, bulk bags with foil inlet, etc.

Just pallet jack will do

Simply use a pallet jack to move the bulk bags, clamp the foil and the suction will follow without supervision and risk of interruption. The bulk bags will be completely emptied.

Bulk material in all variations

For all free-flowing materials

OKTOMAT® ECO emptying stations are ideally suited for all free-flowing bulk materials.

Emptying and conveying of the following raw materials:

- Granulates

- Pellets

- Regrind

- Agglomerates

- Glass fibres

- Rubber cube

- Powder

- WPC

- Activated carbon

- Fine resin

- Food

- Salts

The OKTOMAT®-SOS series is also capable of emptying poorly flowing materials due to its oscillating systems.

OKTOMAT® in practice

Thousands of OKTOMAT® systems are in use worldwide. Most of them work in 3-shift operation under the hardest conditions in these processes:

- Injection moulding

- Extrusion

- Recycling

- Compounding

- Mixing

- Dosing

OKTOMAT® emptying systems are used in the following sectors, among others:

- Automotive

- PVC processing

- Medical Technology

- Raw material handling

- Paper/Film

- Optics

- Packaging

- Recycling

- Cable production

- Lighting

- WPC

- Logistics

- Paper Finishing

- Chemistry/raw materials

- Food

- Connectors

- Flat film production

- Blown film production

OKTOMAT® Video

Two versions

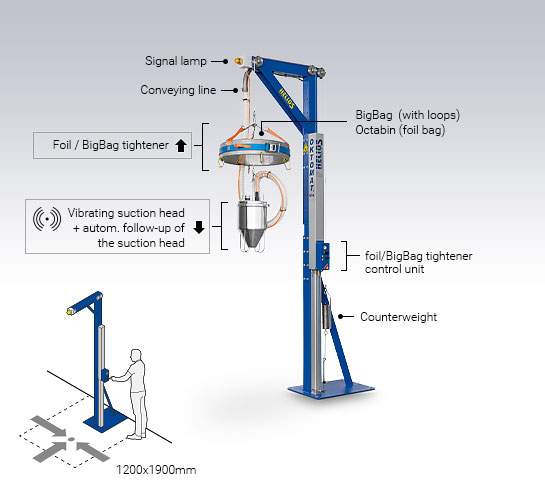

OKTOMAT® ECO – Pedestal version

- Pedestal version made of steel, powder-coated

- 5-fold height adjustable

- Bag tightener tension force 1500 N

- Foil / Big Bag tightener made of stainless steel (Ø 600mm)

for foil inliners and big bag - Suction head type S, conveying line 38/45/50 mm

- automatic complete emptying / automatic bag tightener

- automatic follow-up of the suction head according to filling level via adjustable counterweight

- Special height optional for extra high containers

Placement

- space-saving in width, footprint 1200 mm x 1900 mm

- control access from the side

- approach zone front/left/right

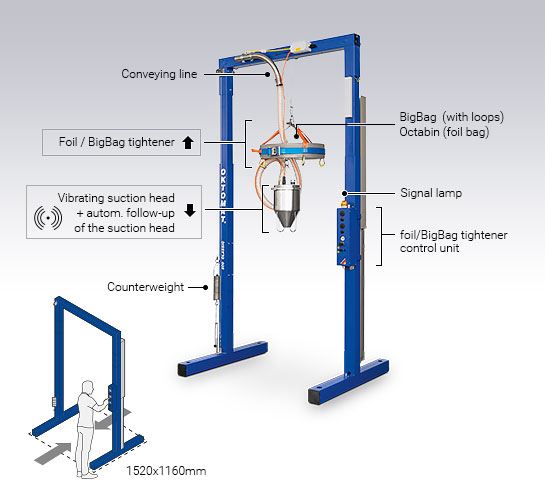

OKTOMAT® ECO Classic – Portal version

- Portal version made of steel, powder-coated

- 7-fold height-adjustable

- Bag tightener tension force 2400 N

- Foil / Big Bag tightener made of stainless steel (Ø 600 mm)

for foil inliners and big bag - Suction head type S, conveying line 38/45/50 mm

- automatic complete emptying / automatic bag tightener

- automatic follow-up of the suction head according to filling

- level via adjustable counterweight

- Special height optional for extra high containers

- Special width optional for extra wide containers

Placement

- space-saving in depth, footprint 1520 x 1160 mm

- control access from the front

- approach zone front/rear

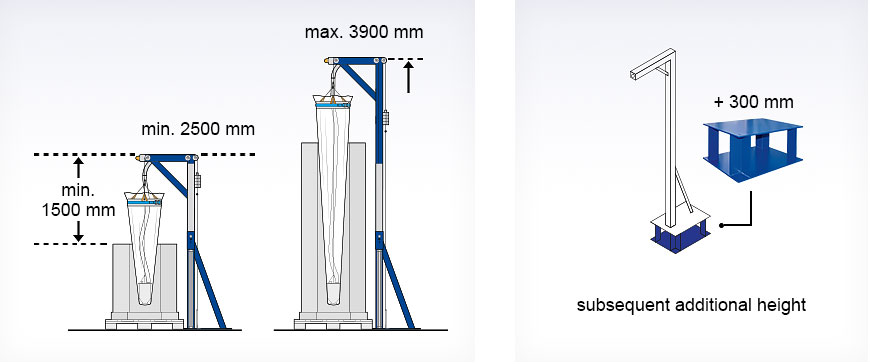

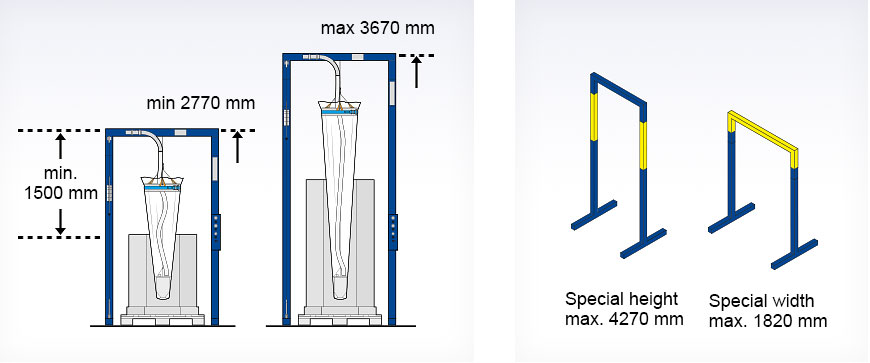

Installation height

OKTOMAT® ECO

- 5-fold height-adjustable

- installation height 3000 mm - 3500 mm

- special height max. 3900 mm by subsequent additional increase

Container height

In order to achieve complete emptying, there must be a minimum distance of 1500 mm between the top edge of the container and the top edge of the emptying station.

OKTOMAT® ECO Classic

- 7-fold height-adjustable

- installation height 2770 mm – 3670 mm

- special height max 4270 mm (+ 600 mm) optional for extra high containers

- special width 1820 mm (+ 300 mm) optional for extra wide containers

Container height

In order to achieve complete emptying, there must be a minimum distance of 1500 mm between the top edge of the container and the top edge of the emptying station.

Vibrating suction head

The OKTOMAT® uses a vibrating suction head instead of the suction pipe and the automatic bag tightening mechanism pulls the foil inlet or big bag upwards. The suction head floats and vibrates in the material and breaks up lumps. The loosened material flows towards the middle and is continuously sucked.

Automatic complete emptying

1. During the suction process, the flexible bulk bag wall is pulled up and inwards via the automatic bag tightening system.

2. As a result, the bag tightens and the bulk material in the border area flows to the central suction point.

3. At the end of the emptying process, the almost empty bulk bag is automatically lifted up from the bottom, enabling a complete material discharging.

Do you have any questions about us or our products?

Just send us a quick message and we’ll gladly get back to you via phone or mail to answer any open questions.

Customer support service by telephone

We will gladly answer all open questions.

or use your own e-mail program:

Privacy policyThe data sent will only be processed for the purpose of processing your request. You can find further information in our data protection declaration. |