Vacuum conveying technology

HELIO®Vac

Suitable conveyor technology for OKTOMAT® discharging stations

Examples

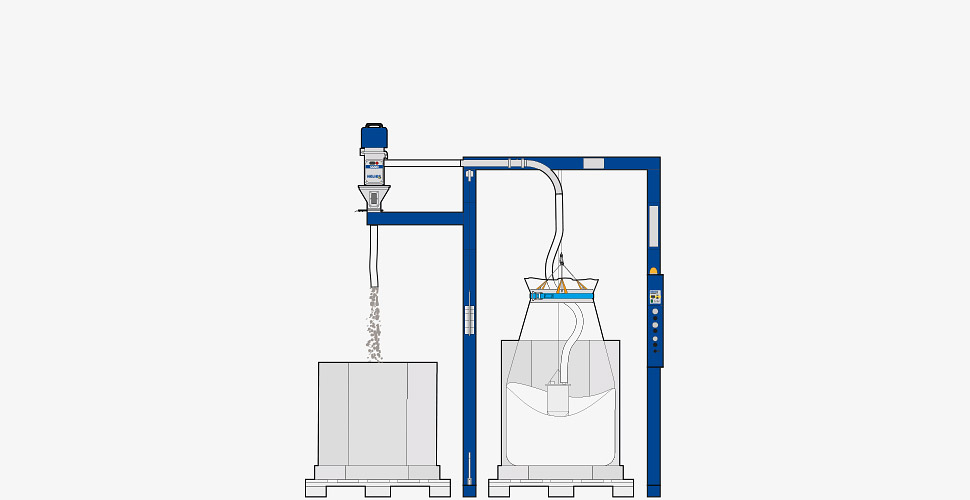

Refilling station

OKTOMAT® portal-/ pedestal-version with cantilever arm + HCA hopper loader

Capacity up to approx. 250 kg/h*

*depending on the conveyed material and conveying distance

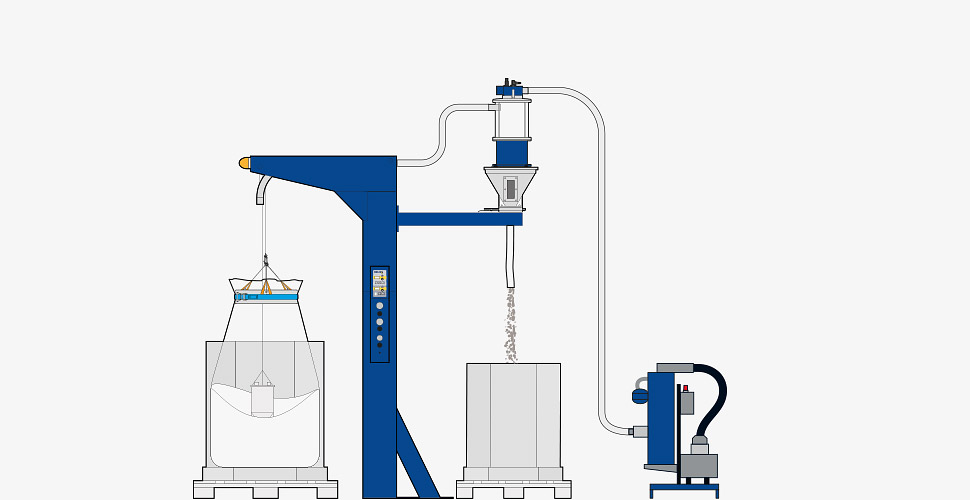

Refilling station

OKTOMAT® SOS portal-/ pedestal-version with cantilever arm + HFE-15K hopper loader and HV vacuum station

Capacity up to approx. 1000 kg/h*

*depending on the conveyed material and conveying distance

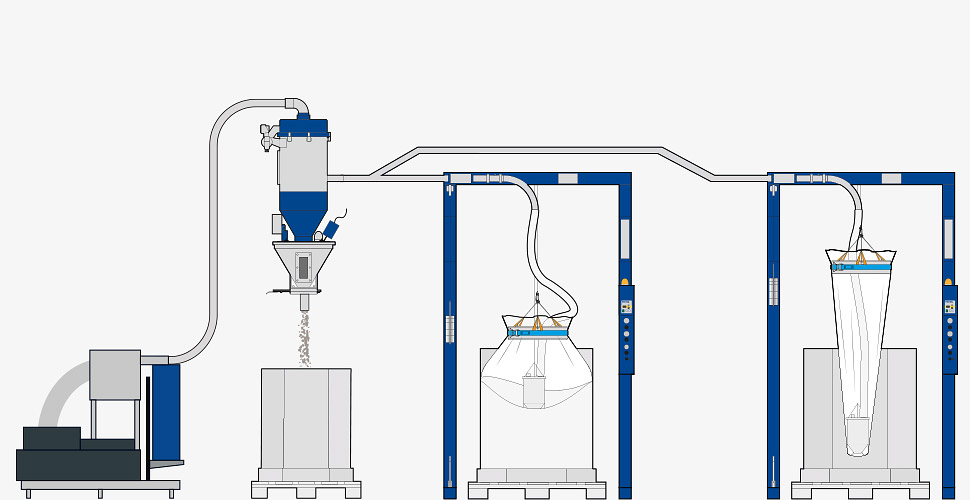

Double station

OKTOMAT® portal-version with switch over function + SFG hopper loader and HVK vacuum station

Capacity up to approx. 5000 kg/h*

*depending on the conveyed material and conveying distance

Vacuum hopper loaders

HFE

Stainless steel/glass vacuum hopper loader with separate conveyor control

Granules

Capacity up to 1000 kg/h

- HFE-15K | 15 liters

- HFE-30K | 30 liters

Conveyor pipe ∅ 50|65 mm

with intermediate container 15/25 liters as an option

SFG

Stainless steel vacuum hopper loader with integrated control

Powder Fine resin Regrind Granules

Capacity up to 5000 kg/h

- SFG-2 | 20 liters

- SFG-3 | 20 liters*

- SFG-6 | 60 liters

Conveyor pipe ∅ 38|50|60|65|80 mm

optionally with intermediate container 25 liters

*(with enlarged filter)

HCA

vacuum hopper loader made of stainless steel with compressed air driven vacuum generator

Powder Fine resin Granules

Capacity up to 250 kg/h

- HCA-2 | 2 liters

- HCA-5 | 2 liters*

Conveyor pipe ∅ 40 mm

with intermediate container 5/15 liters as an option

*(with enlarged filter)

Vacuum stations

HV vacuum station

with 2-stage side channel blower

- 2,5 - 7,0 kW

HVK vacuum station

vacuum station with claw pump

- 4 - 9 kW

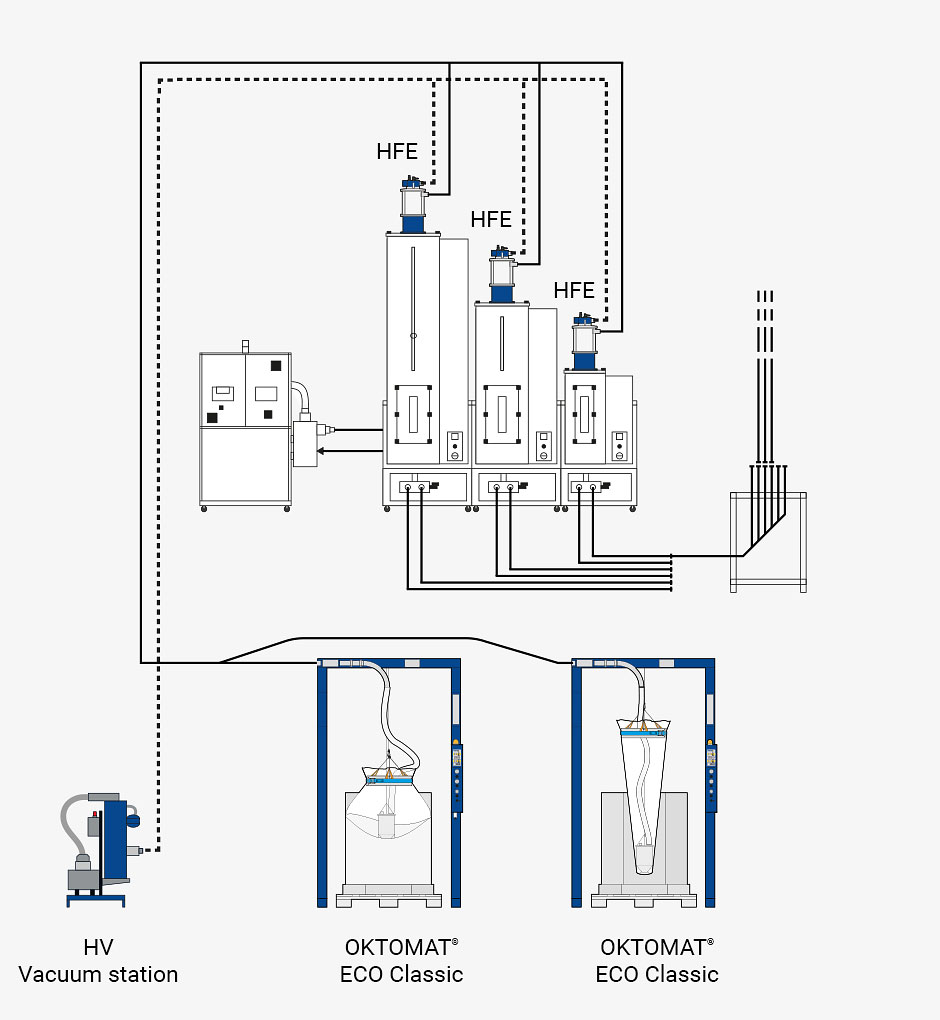

Integration

Integration in central granulate dryer

Integration in internal silo filling

Do you have any questions about us or our products?

Just send us a quick message and we’ll gladly get back to you via phone or mail to answer any open questions.

Customer support service by telephone

We will gladly answer all open questions.

or use your own e-mail program:

Privacy policyThe data sent will only be processed for the purpose of processing your request. You can find further information in our data protection declaration. |