Quality in plastics

Plastic processing, especially injection moulding, requires absolutely pure raw materials without dust, angel hair and other impurities for the production of high-quality parts. Since these often only occur during conveying, HELIO®Clean granulate cleaners are combined conveying and dedusting systems for mounting on the processing machine, which transfer the perfectly dedusted granulate / regrind material directly into the plasticizing unit. When selecting a deduster system, the choice shall be made:

As good as possible, or as good as necessary? We offer both !

HELIOS always has the optimal solution for your dedusting task.

- better part quality

- less scrap

- more regrind can be used

- less machine downtime

Perfect material quality

By a professional material cleaning, the quality of the resin can be brought back to its original state and optically perfect parts can be produced from it.

Example: PMMA raw granulate before and after dedusting.

Cleaning by ion shower

Dust is removed by means of air-floating with a highly effective ion shower. Due to its absolutely new fountain principle, this air washing process is able to perform even the most difficult cleaning tasks perfectly. Dust, chippings, fluff and angel hair can be removed safely.

Problems with insufficiently dedusted resin

Product quality

- combustions (black dots)

- unmelted parts (white dots)

- streaks

- surface problems

- reduced mechanical properties

Injection moulding machine

- clogging and crust formation at the feeding zone

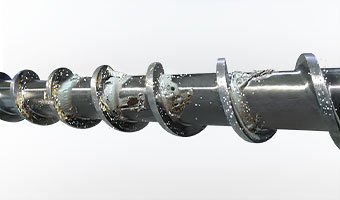

- abrasion on screw and barrel due to charred dust

- frequent machine downtime and high cleaning costs

Practical example: HELIO®Clean 2 conveying and dedusting device on processing machine

Practical example: HELIO®Clean 3 conveying and dedusting device on processing machine

Practical example: combination of HELIO®Clean Pro 10 deduster and JETBOXX® granulate dryer on processing machine

Practical example: HELIO®CLEAN Pro 20 deduster on processing machine

Do you have any questions about us or our products?

Just send us a quick message and we’ll gladly get back to you via phone or mail to answer any open questions.

Customer support service by telephone

We will gladly answer all open questions.

or use your own e-mail program:

Privacy policyThe data sent will only be processed for the purpose of processing your request. You can find further information in our data protection declaration. |