Dryer controls

JETBOXX®

Series WINneo®2

| WINneo®2 | ||

| Quick selection keys | Drying program / drying intensity |  |

| Filling level calculator |  |

|

| System settings |  |

|

| Weektimer |  |

|

| Conveying ON/OFF |  |

|

| Conveying points | Conveying point 1 (drying container filling) - 1 Component with dedusting |

|

| Conveying point 1 (drying container filling) - 2 Components with dedusting |

|

|

| Conveying point 1 (drying container discharge aid) Discharge aid with air pulses |

|

|

| Conveying point 2 (processing machine feeding) - 1 Component with dedusting |

|

|

| Functions | Dew point display with alarm function |  |

| Overdrying protection |  |

|

| Limitation of the drying temperature with adjustable tolerance |

|

|

| Interfaces | Modbus RTU |  |

| TCP/IP |  |

|

| OPC-UA |  |

|

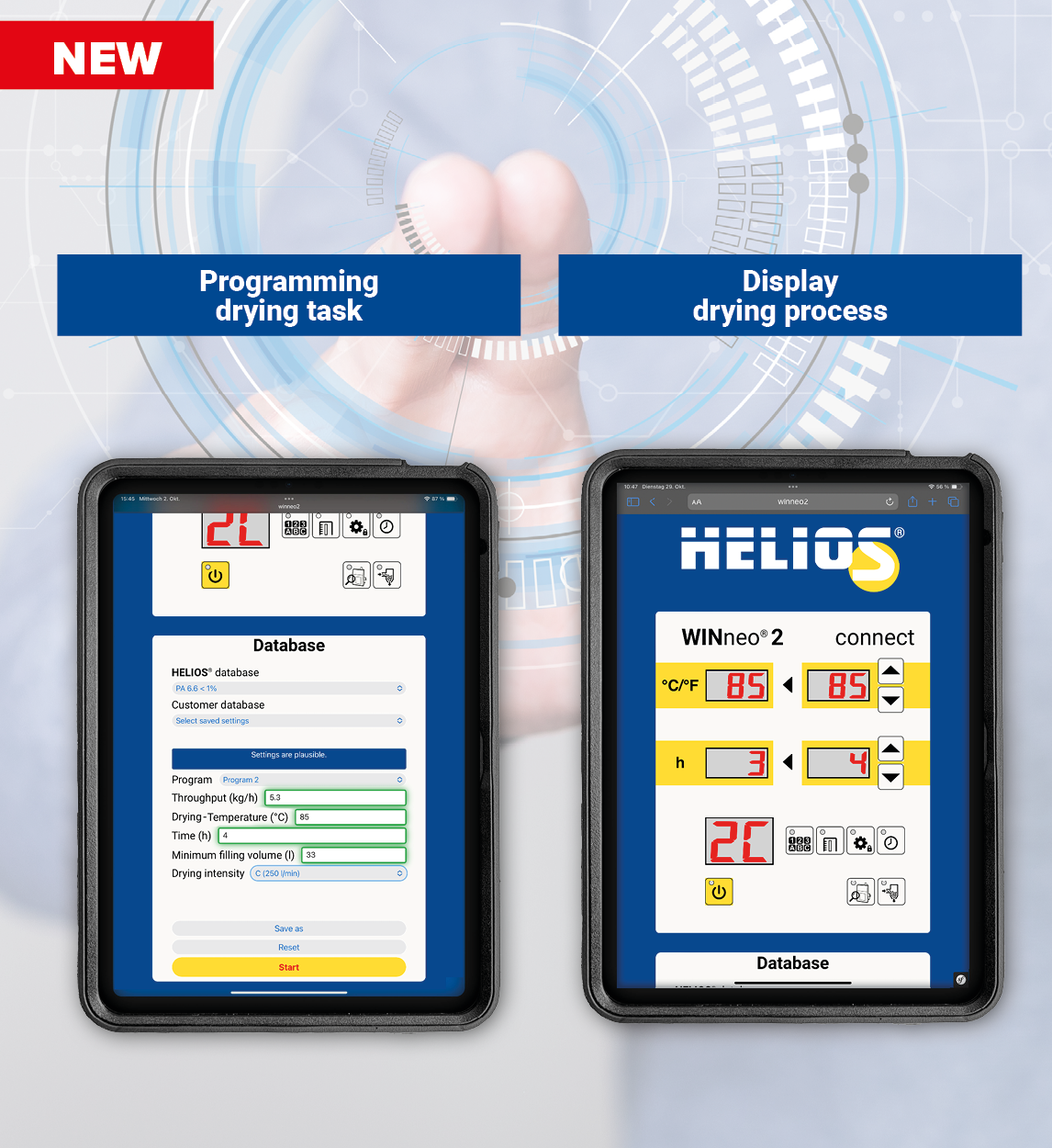

| NEW | Remote Control / WINneo®2 connect |  |

standard

|

||

optionally

|

||

Perfect drying results with WINneo® 2 series

3 drying programs, 3 drying intensities and 3 conveying controls

Intuitive change of drying programs with drying intensities via the function button

Dryer- and conveyor controls

Program 1

Batches-Drying

|

Drying program 1 C for drying batches

|

||

|

Drying of one container filling with maximum drying intensity over a selected time.

|

||

|

Function: A batch of granulate is dried for a certain time and temperature with maximum drying intensity.

|

||

Program 2

Continuous drying program with pre-drying

after material change

|

Continuous drying program in three different drying intensities

with pre-drying (in level C) |

||

|

2 A

Drying intensity A Volume flow min. |

2 B

Drying intensity B Volume flow medium |

2 C

Drying intensity C Volume flow max. |

|

Function: One full container of granulate is pre-dried at a selected temperature and drying time with maximum intensity.

|

||

By pressing the key, the three drying programs (1 | 2 | 3) can be selected.

Program 3

Continuous drying program for constant operation

|

Continuous drying program in three different drying intensities

without pre-drying |

||

|

3 A

Drying intensity A Volume flow min. |

3 B

Drying intensity B Volume flow medium |

3 C

Drying intensity C Volume flow max. |

|

Function: Dried granulate is continuously removed from the drying container and automatically refilled.

|

||

Performance Level |

Dry air volume flow |

Dry intensity |

||

|---|---|---|---|---|

Air level A |

Air level B |

Air level C |

||

| JETBOXX® 3 | l/min | 40 | 60 | 80 |

| JETBOXX® 6 | l/min | 40 | 60 | 80 |

| JETBOXX® 12 | l/min | 85 | 115 | 150 |

| JETBOXX® 24 | l/min | 85 | 115 | 150 |

| JETBOXX® 20 | l/min | 85 | 115 | 150 |

| JETBOXX® 30 | l/min | 85 | 115 | 150 |

| JETBOXX® 50 | l/min | 125 | 200 | 250 |

| JETBOXX® 75 | l/min | 150 | 225 | 300 |

| JETBOXX® 200 | l/min | 240 | 340 | 450 |

WINneo® 2 connect - offers maximum operating comfort

- HELIOS® material database

- Freely programmable database

- Intuitive operation

- Wireless remote control

WINneo® 2 fully OPC UA

Future-proof thanks to modern communication –

system JETBOXX® as a key component of digitalisation.

WINneo® 2 fully OPC UA offers you all the benefits of WINneo® 2 connect and also allows you to integrate your dryer into an industrial, digital network.

- Future-proof solution

- Simple installation via Ethernet

- Platform-independent

- Can be integrated with cloud, ERP systems or dashboards

- Standardised interface, no customisation required

- HELIOS® dryers are in compliance with OPC UA

Do you have any questions about us or our products?

Just send us a quick message and we’ll gladly get back to you via phone or mail to answer any open questions.

Customer support service by telephone

We will gladly answer all open questions.

or use your own e-mail program:

Privacy policyThe data sent will only be processed for the purpose of processing your request. You can find further information in our data protection declaration. |