Variable pre-drying station

JETBOXX®

Base frame with docking system for JETBOXX® top mounted dryers

HELIOS top-mounted dryers are positioned on a base frame with docking plates.

The drying containers can be removed and carried to the processing machine. They are mounted directly on the feeding zone and the dried material can be processed. If the material should be kept dry on the machine, a JETBOXX® docking plate can be used, that is connected to a dryer control.

Applications:

- Pre-drying station for quick material change

- Drying station for sample batches

- Batch drying in small sizes / sampling

- Laboratory applications

- Cleanroom supply with hermetically sealed drying containers

- Drying container parking station

- Stand-alone station / dryer as insular solution

If the task changes, the components can be easily exchanged or used top-mounted dryers again.

Suitable for the whole JETBOXX® product range up to 30 liters.

- WINneo® / WINsystem® dryer control

- Suction or discharge devices

- Can be combined with external conveying devices

If the task changes, the components can be easily exchanged or used as top-mounted dryers again.

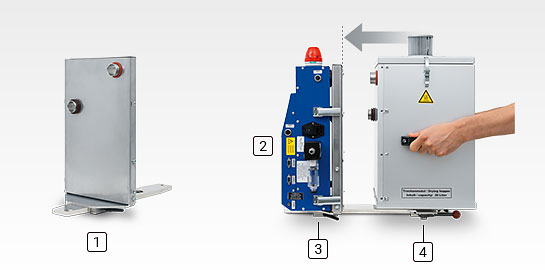

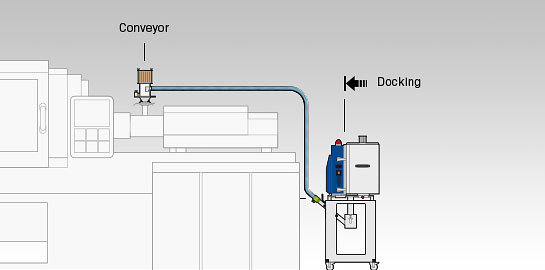

JETBOXX® docking system

The docking plate serves as holding device for the dryer control and as docking station for changing drying containers, mounting with L-shape sliding guide on sliding rail. When the drying time has elapsed, the hermetically sealed containers can be moved comfortably by rack to the point of processing.

- Docking plate

- JETBOXX® dryer control

- L-shape sliding guide with locking lever

- Drying container with L-shape sliding guide and locking lever

Docking variants for removable drying containers

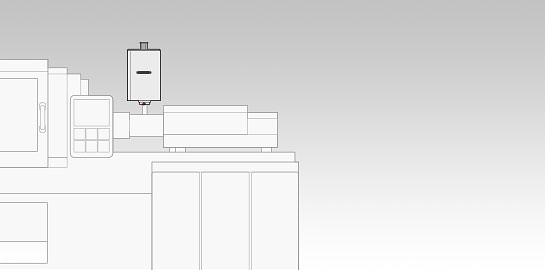

A variant

The dryer filled with dried granules is attached directly onto the feed section of the injection molding machine via a sliding rail.

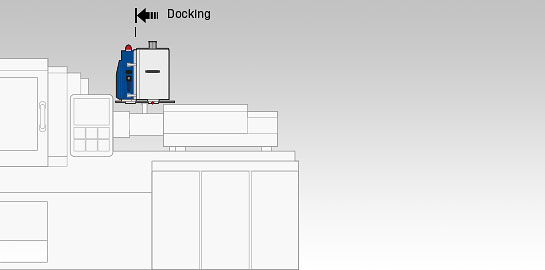

B variant

A docking plate with dryer control is fixed on the injection molding machine. The drying containers are docked via a sliding rail.

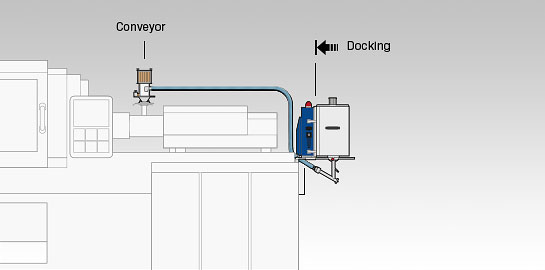

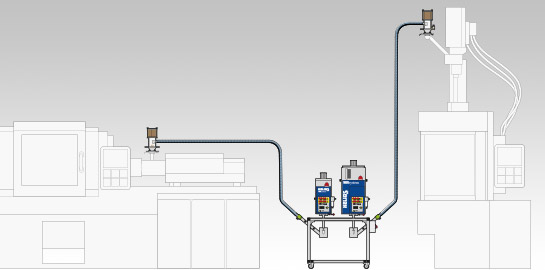

C variant

The docking plate including the dryer control is fixed directly on the injection molding machine. The drying containers are docked via a sliding rail. The dried granules are conveyed via a suction device onto the injection molding machine.

D variant

The docking plate and dryer control are mounted on a base frame / stand-alone station.

E variant

Application as stand-alone station / dryer as isolated dryer.

System components

Base frames

|

|

|

|

| 2-fold unit | 3-fold unit | 4-fold unit | |

| Height [mm] | 739 | 739 | 739 |

| Width [mm] | 1179 | 1679 | 2100 |

| Depth [mm] | 683 | 683 | 683 |

| Electrical power supply | centralized power supply for all docking stations (optionally) | ||

| Sliding rail | beveled on both sides, for L-shape sliding guides 80×15mm oder 80×20mm | ||

Mobile base frame

|

|

| For transport from pre-drying station to the point of consumption, sliding rail 80×15mm or 80×20mm |

Option: Different outlet- / discharge devices |

Do you have any questions about us or our products?

Just send us a quick message and we’ll gladly get back to you via phone or mail to answer any open questions.

Customer support service by telephone

We will gladly answer all open questions.

or use your own e-mail program:

Privacy policyThe data sent will only be processed for the purpose of processing your request. You can find further information in our data protection declaration. |