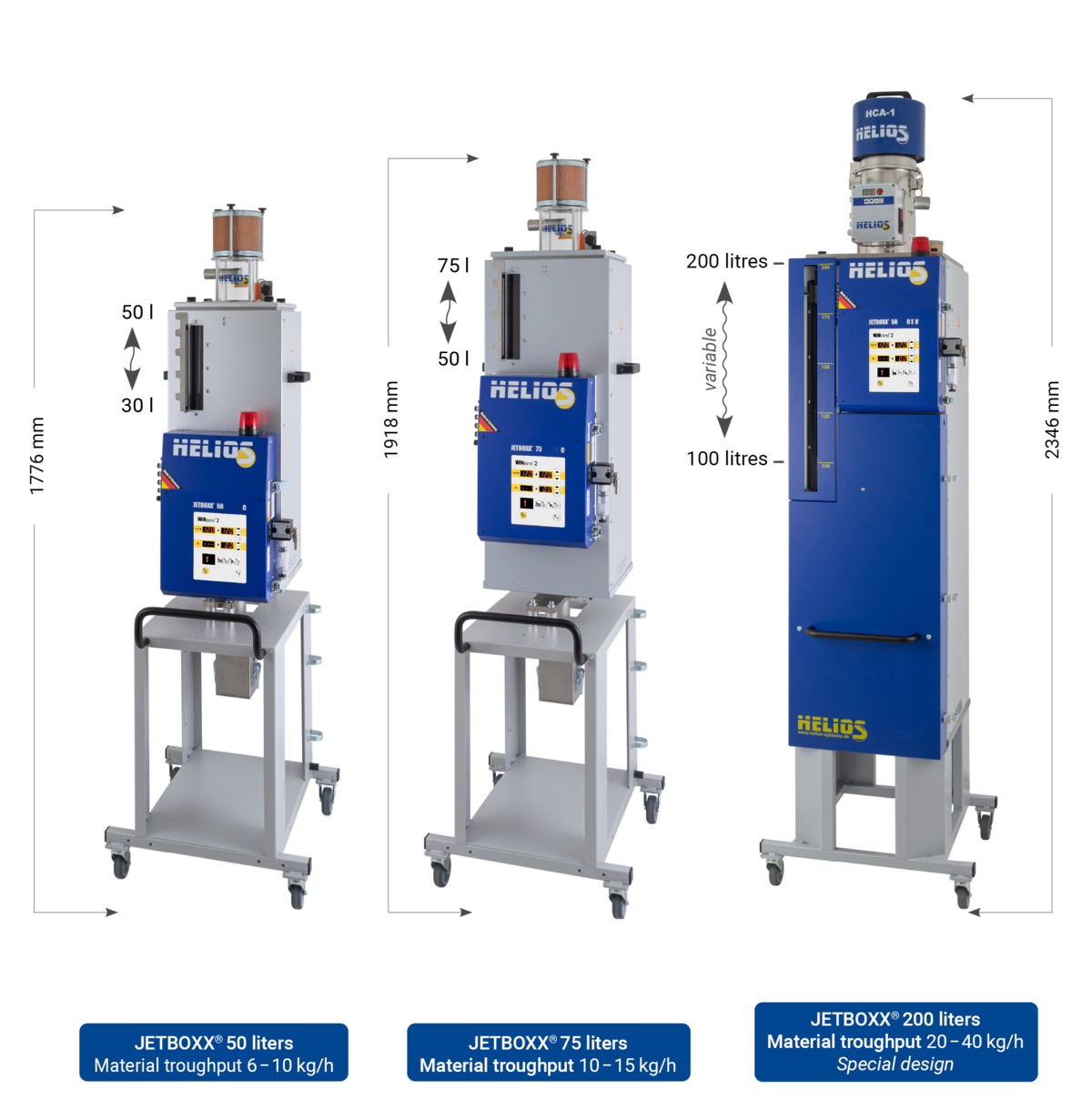

Stand-alone dryers

JETBOXX®

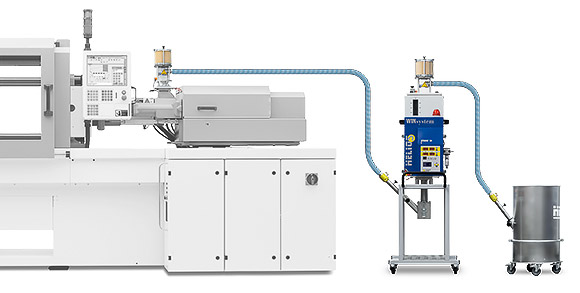

Stand-alone dryers to the processing machine

Placed next to the processing machine and conveying to the injection unit.

Stand-alone dryers can be used anywhere, where top-mounted dryers fail because of weight / or space reasons. Assembly of the system components on a base frame for a drying before / while the processing with conveying of the dryed granules onto the injection unit.

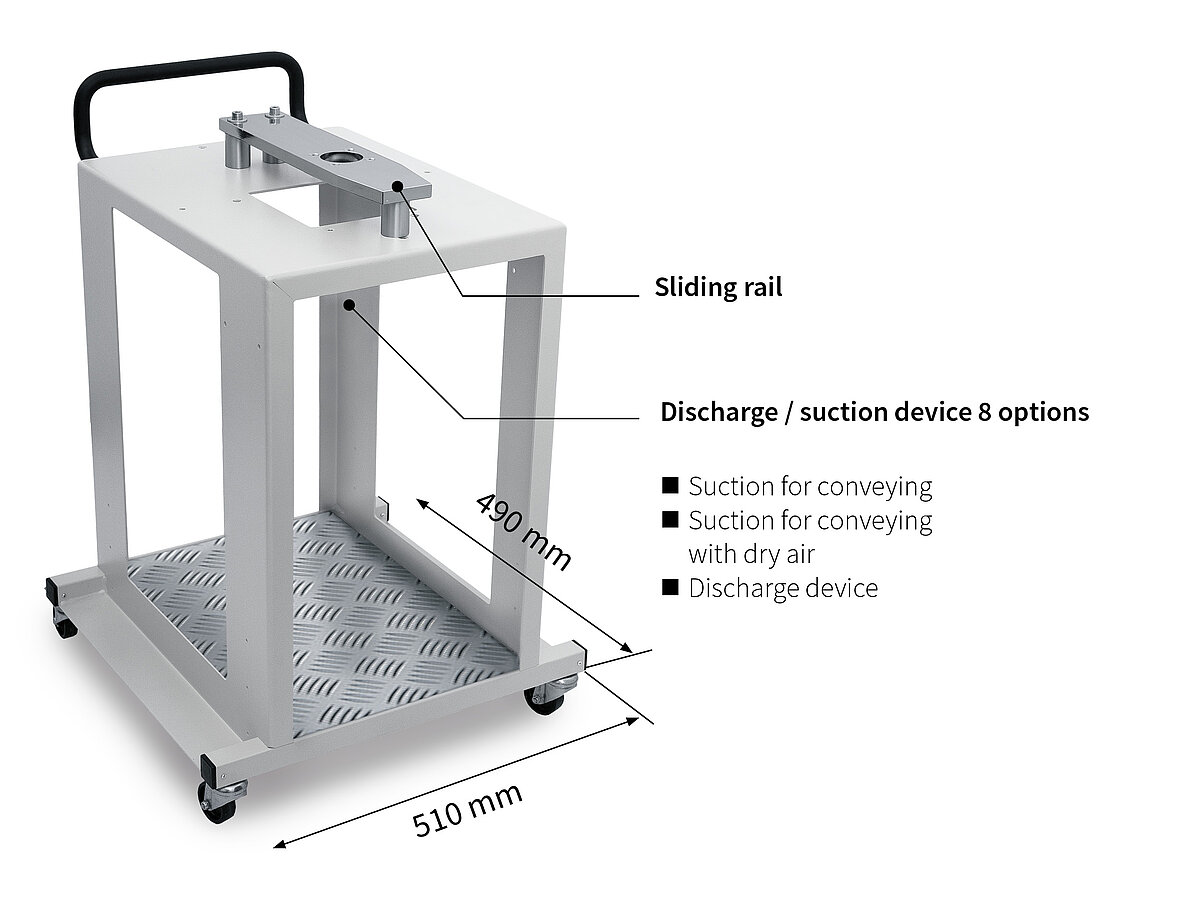

Minimal space requirement.

Movable base frame: 510 × 490 mm

(special design ST-200: 600 × 600 mm)

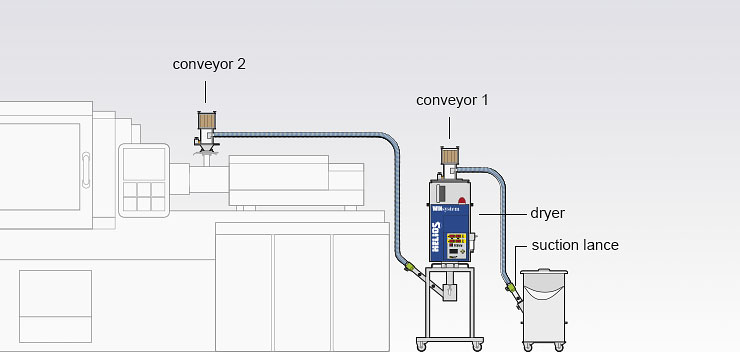

Examples of use

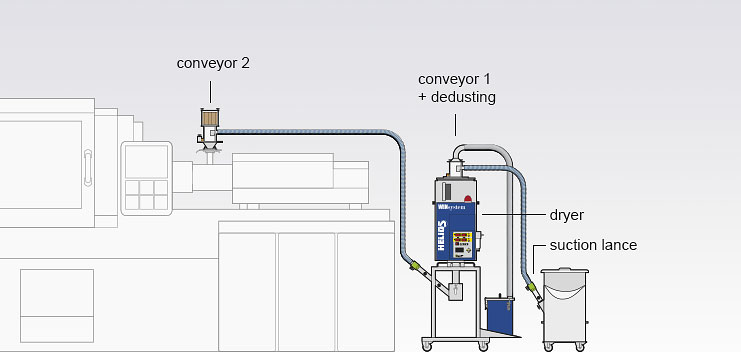

A variant

Conveying and drying of one component directly next to the injection moulding machine and conveying of the dried material to the feeding zone. Conveying height up to 6 m possible. Optionally with/without dried air conveying.

+ Control for conveyors 1 and 2 included in WINneo® 2.

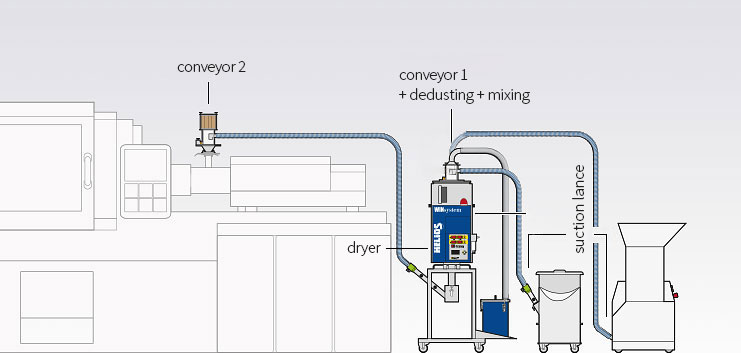

B variant

Conveying, dedusting and drying of one component next to the injection molding machine. Conveying of the dried material to the feeding zone. Optionally with/without conveying with dried air.

+ Control for conveyors 1 and 2 included in WINneo® 2.

C variant

Conveying, dedusting and drying of two components next to the injection molding machine. Conveying of the dried material to the feeding zone. Optionally with/without conveying with dried air.

+ Control unit for conveyors 1 and 2 included in WINneo® 2.

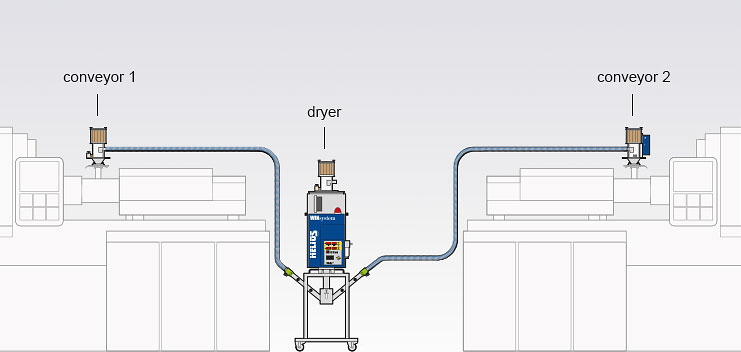

D variant

Example: Feeding of two machines with dried material. Optionally with/without conveying with dried air.

Conveying to the feeding zone

The second conveyor control is included in the JETBOXX® dryer control.

Conveying height up to 6 m

Because of their construction, HELIOS compressed air conveyors are able to convey the material gently up to 6 m.

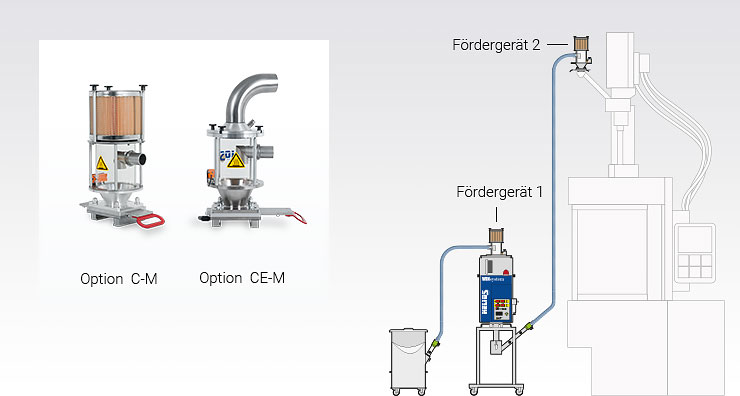

2nd conveyor: conveying onto feed zone

By using ambient or pure dry air, the material can be conveyed from suction box at dryer out to the feeding zone, depending on the hygroscopicity of the dried granulate/ground material.

Compressed air conveyors

Suction devices

Suction devices with dry air conveying

3 new types of suction devices allow a 100 percent avoidance of post humidification of the dried material in the waiting or conveying phase.

Suction / discharge devices

For conveying the dried granulate with Venturi suction lances or for discharging the material for cleaning purposes, there are 4 devices available.

|

|

|

|

|

|

|

|

|

| XT-1 mini | XT-1 | XT-2 | Conveying with dry air | Moveable base frame | X-1 | X-2 | A1 | A2 |

| Mini suction device with integrated Venturi suction lance and dry air conveying. For small throughputs up to 5 kg/h Conveying pipe: 22 mm |

Material suction for HELIOS Venturi suction lance, dry air conveying with one suction point DN 32 |

Material suction for HELIOS Venturi suction lance, dry air conveying with two suction points DN 32 |

Closed conveying system. Venturi principle without suction of ambient air. | For conveying the dried granulate with Venturi suction lances or for discharging the material for cleaning purposes, there are 4 devices available. |

1- fold Suction device for HELIOS Venturi suction lance DN 32 |

2- fold Suction device for HELIOS Venturi suction lance DN 32 |

Discharge nozzle, vertical | Discharge nozzle, sloping |

JETBOXX® control

Do you have any questions about us or our products?

Just send us a quick message and we’ll gladly get back to you via phone or mail to answer any open questions.

Customer support service by telephone

We will gladly answer all open questions.

or use your own e-mail program:

Privacy policyThe data sent will only be processed for the purpose of processing your request. You can find further information in our data protection declaration. |